The Hidden Costs of Labor

It’s time to rethink robot-labor groupthink

A readily available workforce rendered the cost of legacy AGV technology unreachable for most in material handling. Today, the calculus has changed. Modern AMR technology is being matched by persistent labor shortages and a nearly 50% cost premium that is largely unaccounted for. Do you know your hidden labor costs?

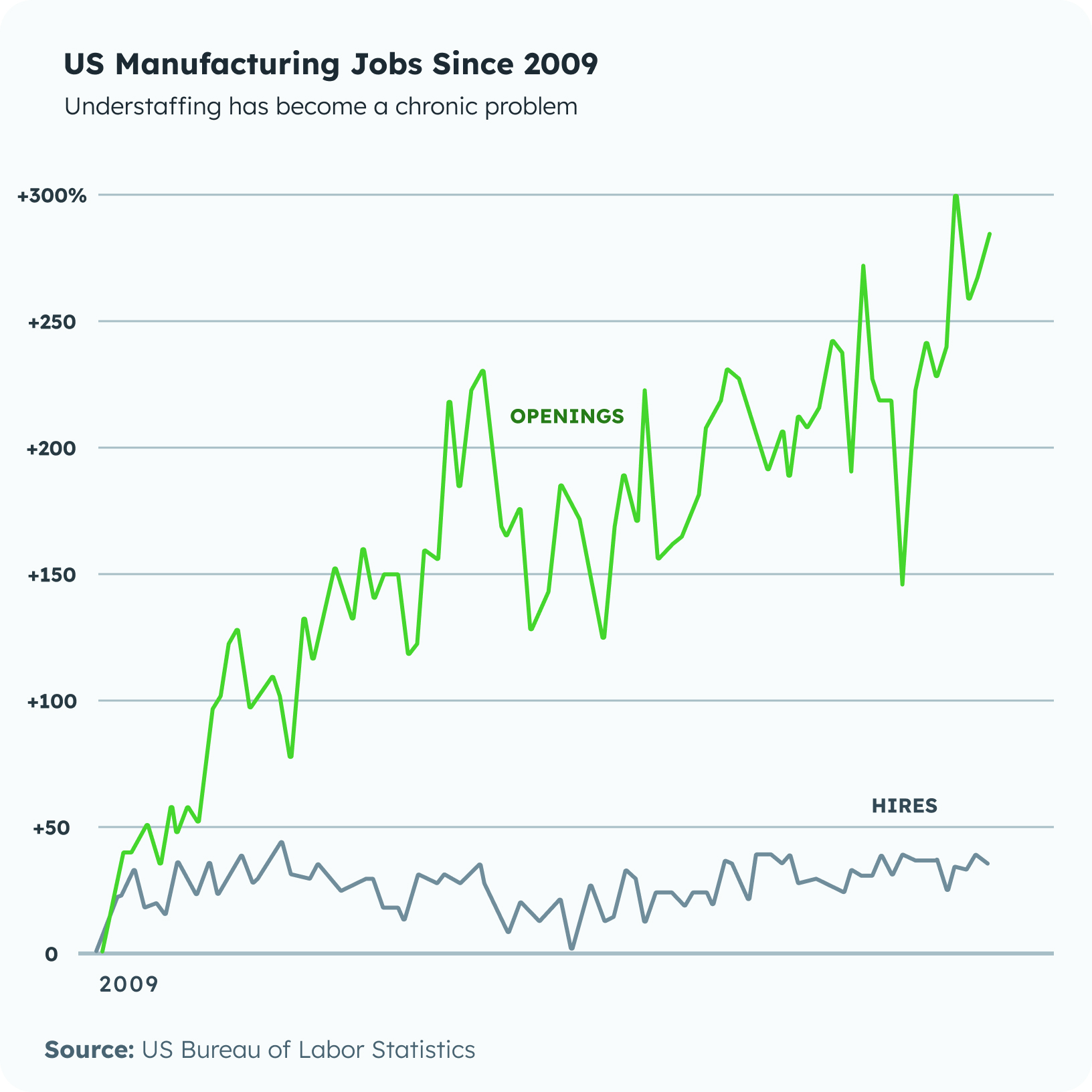

Hidden cost: Labor Availability

The workers you can’t hire are costing you

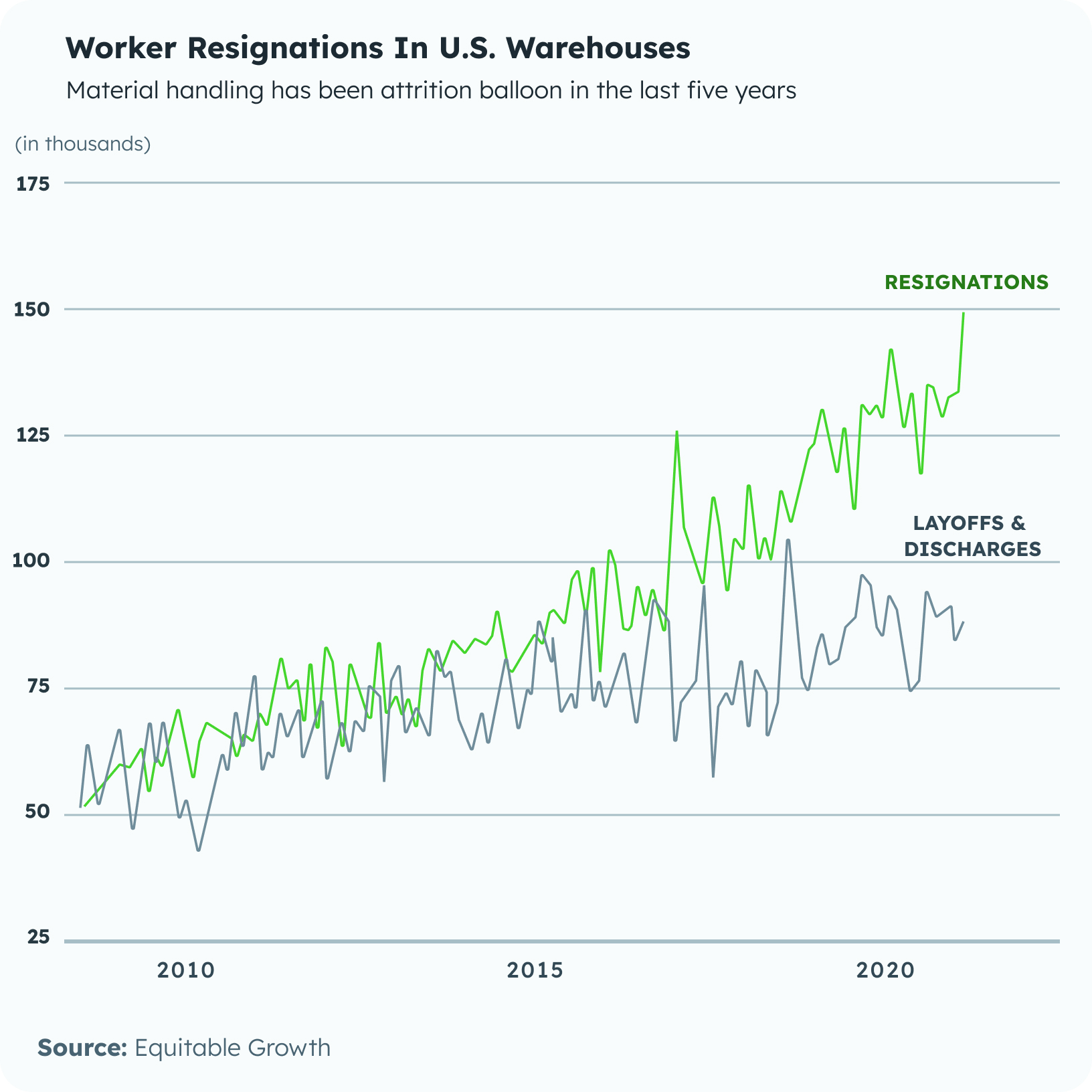

Existing and newly entering people into the workforce have choices. The more fluid nature of today’s workforce, reliability, cost and retention of readily-available labor will only continue to get worse.

73%

of warehouses can’t hire enough workers

575k

unfilled warehousing jobs in the U.S.

Hidden cost: Turnover

You lose money when you lose people

The high turnover rates in material handling coupled with the costs to replace a departed worker, is a recipe for disaster. The average warehouse with 100 FTE spends more than $365k per year on turnover costs alone!

43%

industry turnover rate

20%

cost of salary to replace a worker

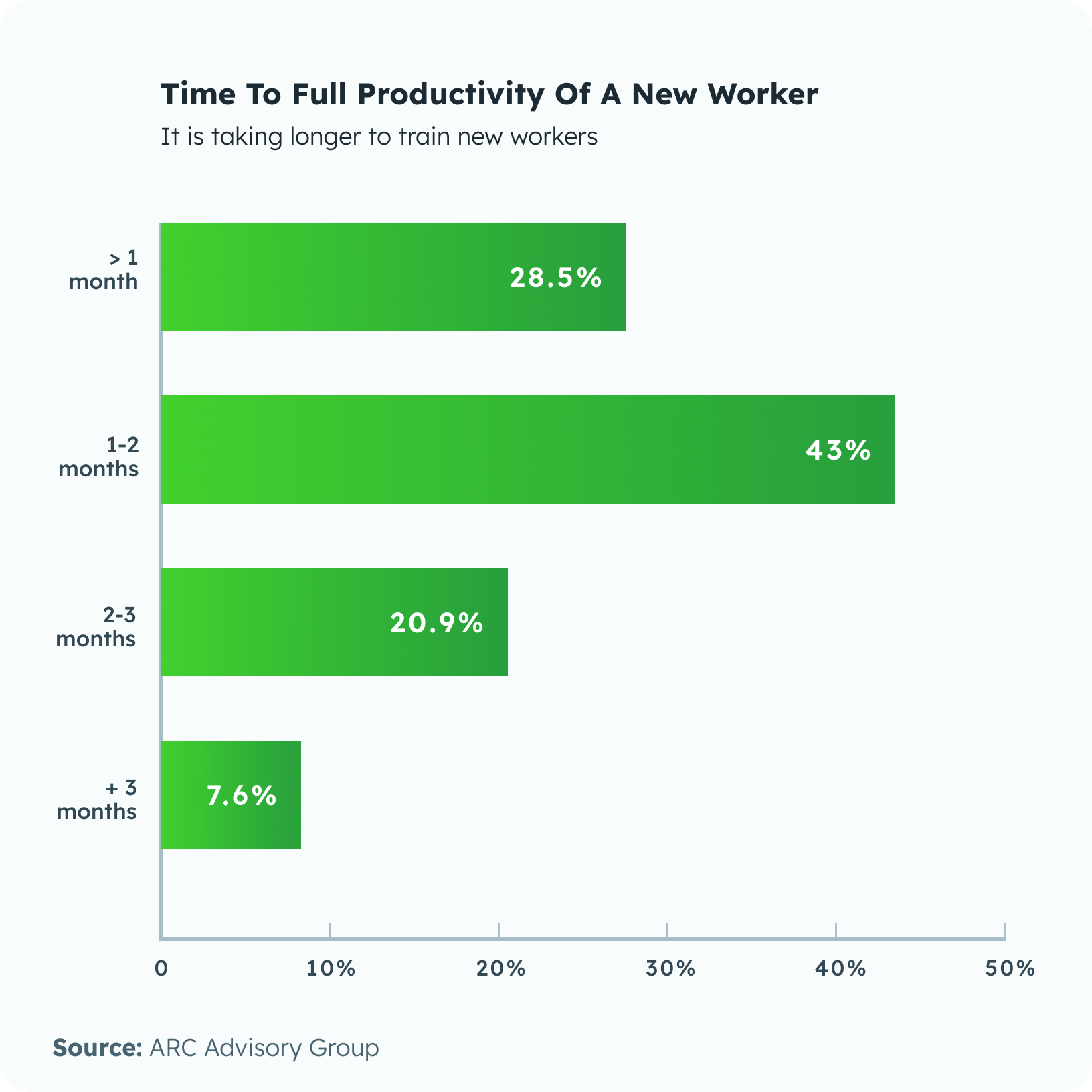

Hidden cost: Training

Workers need to get up to speed

Training is one of those expenses that many operations take for granted. On average, 43% of your staff will need to be trained each year resulting in recurring cost and lost productivity.

$1500

training cost per worker

7%

productivity hit due to onboarding new employees

Hidden cost: Understaffing

The drag of your missing worker

Understaffing has a significant impact on throughput and carries both additional costs and lost revenues. And the cost of these absences translates into a productivity hit to your existing workers who have to pick up the slack.

2x

more likely to quit due to understaffing

37%

understaffing in warehousing

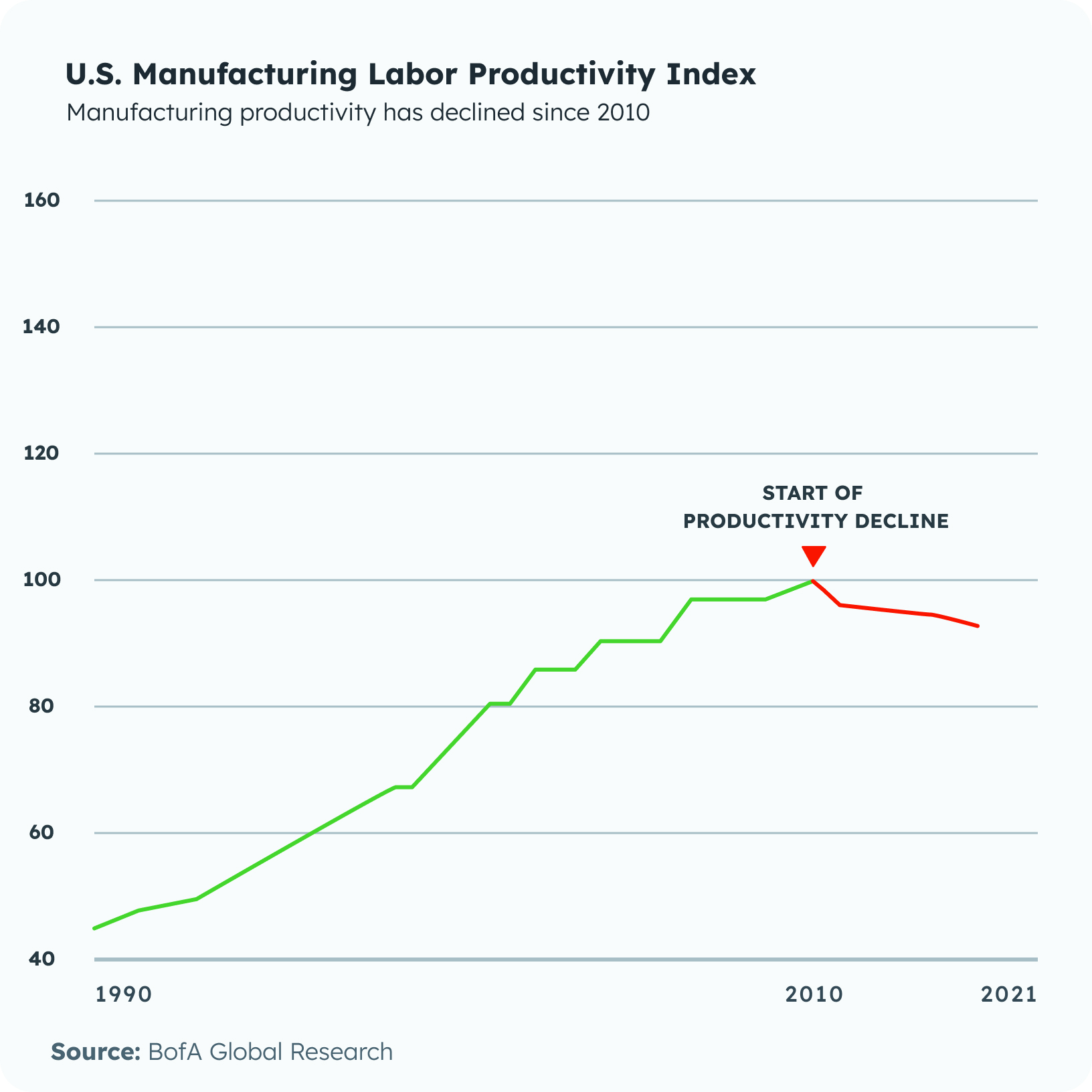

Hidden cost: Lost Productivity

The labor-only double whammy

Along with persistent understaffing, the average U.S. worker is LESS productive today than they were in 2010. So even if you can fill those roles, you have an uphill battle to keep them at work and more productive.

20%

or more in lost output due to understaffing and productivity losses

4%

decrease in average worker productivity since 2010

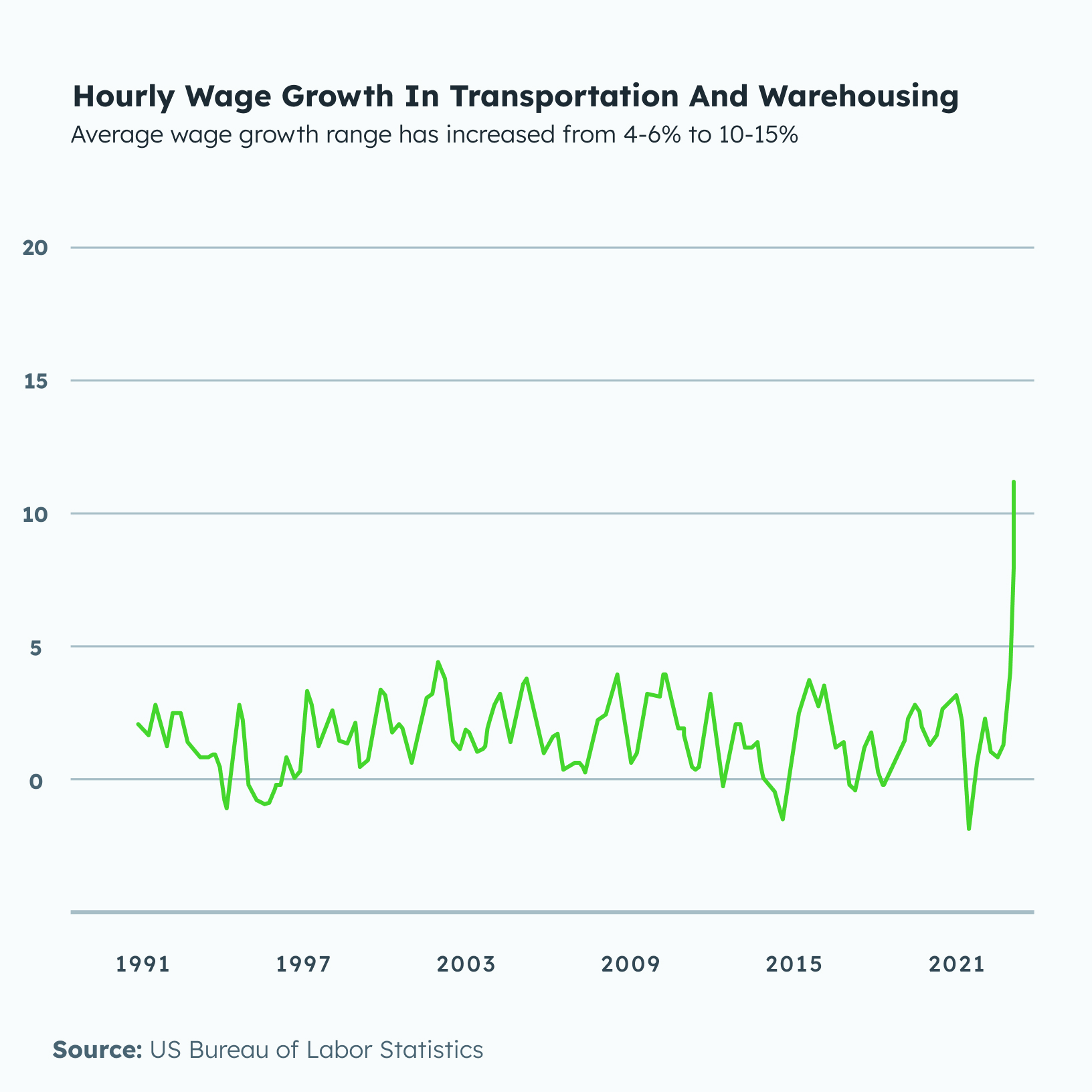

Hidden cost: Inflation

Wage increases that defy gravity

Labor costs will continue to rise. And all of the factors mentioned above combined with external inflationary pressure means that cost of your workers is only going one way. Up.

10-15%

wage increases in the last two years

Hidden cost: Safety

The cost of safety is material

Workers can become quite skilled at highly repetitive tasks but accidents will happen from time to time. Even minor incidents cost tens of thousands, and happen more frequently than you might expect.

1/10

manned forklift will be

involved in an accident

each year

$250k

average cost of

injuries per

warehouse/year

IDC White paper

Making the business case for supply chain automation

How can manufacturing facilities and warehouses manage the complexity of a post-covid marketplace? See how the IDC predicts intelligent automation will change the world.

“…the hidden costs of labor, particularly in the current environment, have been undercounted by as much as 50%.”

Trusted by industry leaders

and those in the know

Let’s go

Optimize your critical workflows right now

Have questions about what Vecna can do for you? Tell us about yourself and an automation expert will be in touch shortly.

Thank you for getting in touch

We aim to respond to all messages within 1-2 business days.

In the meantime you might be interested in some of these resources.