Why RaaS, Why Now?

Robotics-as-a-Service (RaaS) pricing models emerged in the early 2010’s. By 2018, the industry began to understand the benefits of RaaS more deeply. That year, Rian Whitton at ABI Research estimated that the installed base for RaaS will grow from 4,442 units in 2016 to 1.3 million in 2026, while annual revenues for RaaS providers are expected to increase from $217 million in 2016 to nearly $34 billion in 2026.

Now, with 2020 in the rearview mirror, the benefits of RaaS has become amplified. RaaS will likely see a greater surge in popularity and acceleration to the predicted timeline.

As proved in 2020, manufacturing, distribution, and warehousing organizations that adapt quickly to evolving conditions survive and thrive. Now, planning for Black Swan events has become a top consideration for global supply chain companies, as David Clear, Vecna Robotics CRO, and friends from Highjump Körber Logistics, GEODIS, and Interact Analysis discussed in October. A RaaS financing model is one way to preserve capital, adapt quickly, and remain operationally efficient for whatever comes next.

Five Ways RaaS Benefits Your Automation Goals

- No up-front costs. For many, capital expense approvals delay the implementation of new technology, and require up-front investment which can drain savings. Moving your AMR and AGV purchase to an operational expense opens up more freedom to use discretionary funds and accelerates timelines for deployment. This ensures operational savings are kept in a rainy day fund should a new crisis emerge.

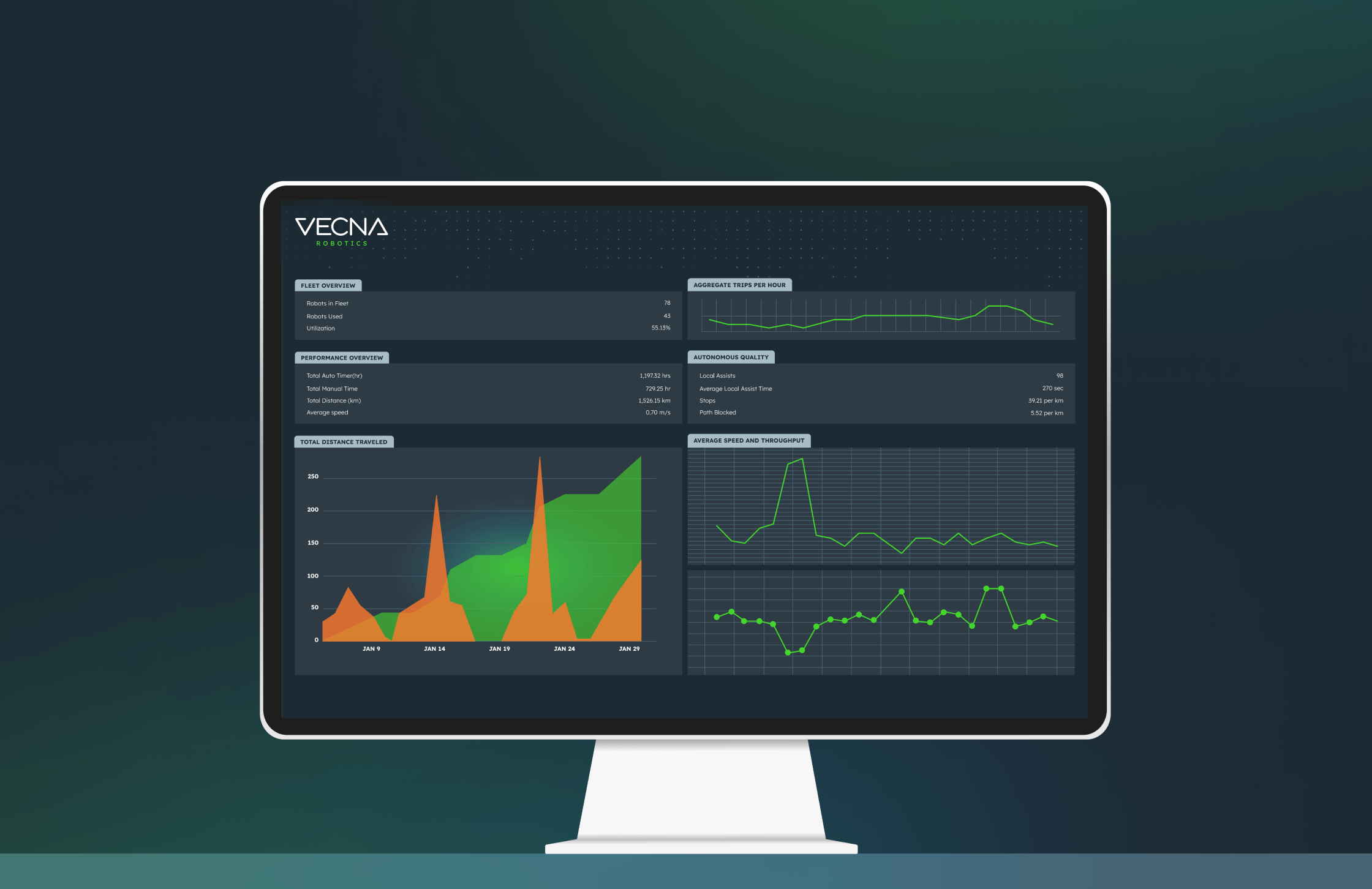

- All-inclusive pricing. Robotics-as-a-Service factors in 100% of costs included in a traditional robotics deployment. This includes subscription to the software platform, deployment (shipping, IT integration, and facility mapping), training and support (including 24/7 US-based support), and maintenance.

- Immediate cash flow improvement. Realize immediate ROI by changing the cost structure from a one-time up-front cost to smaller monthly fees while maintaining cash liquidity.

- Fast implementation. Because RaaS typically requires a cloud-based IT architecture, deployment can be as fast as 4 weeks from purchase order to Go-live.

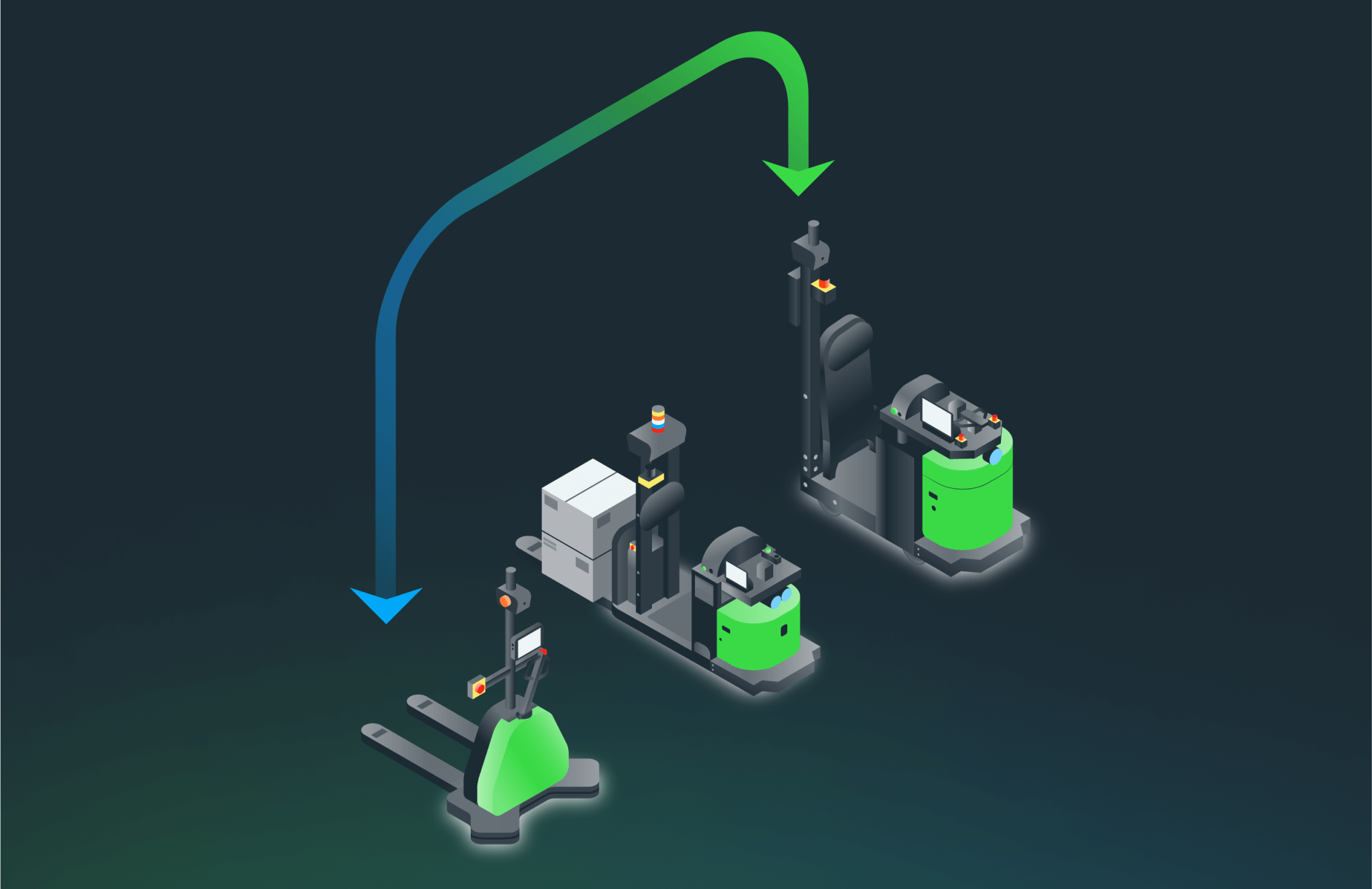

- Easy to scale. Under a RaaS model, the AMR vendor deploys, connects, and upgrades self-driving materials handling equipment via cloud-based IT networking. This way, organizations can rapidly spool up production, reduce the upfront installation costs, and adjust workflows, routes, and fleet sizing on the fly.

Additional Benefits of a Cloud-based Robotics-as-a-Service Solution

In addition, with the IT network already in place, AMR vendors can upgrade or scale down the system quickly, based on changing business needs. For example, it is easy to:

- Push software upgrades to the whole fleet of vehicles without customer intervention.

- Increase fleet size and put new vehicles to work without a long deployment process.

- Swap out old robots for new ones as new hardware becomes available.

This keeps floor space clear and preserves people hours. In addition, Robotics-as-a-Service makes it easy to adapt to changing workflows. In other words, a facility can deploy a new robot to do a new job while returning the old robot to the vendor.

RaaS for Operational Resiliency

In conclusion, a cloud-based RaaS model can provide the backbone for greater operational resilience – a necessity in today’s unpredictable industrial landscape. In addition to scaling easily, getting started quickly, and extending your workforce, RaaS is a way to create financial resilience. Use the capital saved plus the returns from up to 30% increase in operational efficiencies to invest in future automation. RaaS is an enabler for greater gains downstream.

Learn more about how RaaS can benefit your bottom line.