The advent of Automatic Guided Vehicles (AGVs), also commonly referred to as Automated Guided Vehicles, caused a sharp shift upward on the evolutionary scale for warehouse operations. AGV systems have proven to be an efficient way of moving goods around a warehouse facility with minimal human input, reducing costs and improving safety simultaneously.

What is an AGV?

Automated Guided Vehicles (AGVs) are material handling systems used to transport materials and products within facilities such as factories, warehouses, distribution centers, and shipping areas. AGVs are designed to operate autonomously to pick and load products and transport them from one location to another.

They are equipped with sensors and software that allow them to navigate, detect obstacles, and avoid collisions with other vehicles and objects. AGVs can be used to handle a wide range of products and materials, are easily integrated into existing operations, and are a safe and secure way to increase process efficiency and improve business profitability by reducing human error and labor costs while increasing productivity.

This article gives an overview of AGV systems:

- Differences of AGVs and AMRs

- Basic types of AGVs

- How they’ve changed over time

- How they’re used

- The benefits of AGVs

As we dive into the various AGV solutions, you can glimpse the future, giving you a helpful framework for making informed decisions when contemplating which automated solution is right for your business.

With over 5 billion pallets in circulation and 70% of the total cost of moving those pallets being labor – combined with severe labor shortages – automatic guided vehicles indeed represent a durable solution for the future.

AGVs versus AMRs

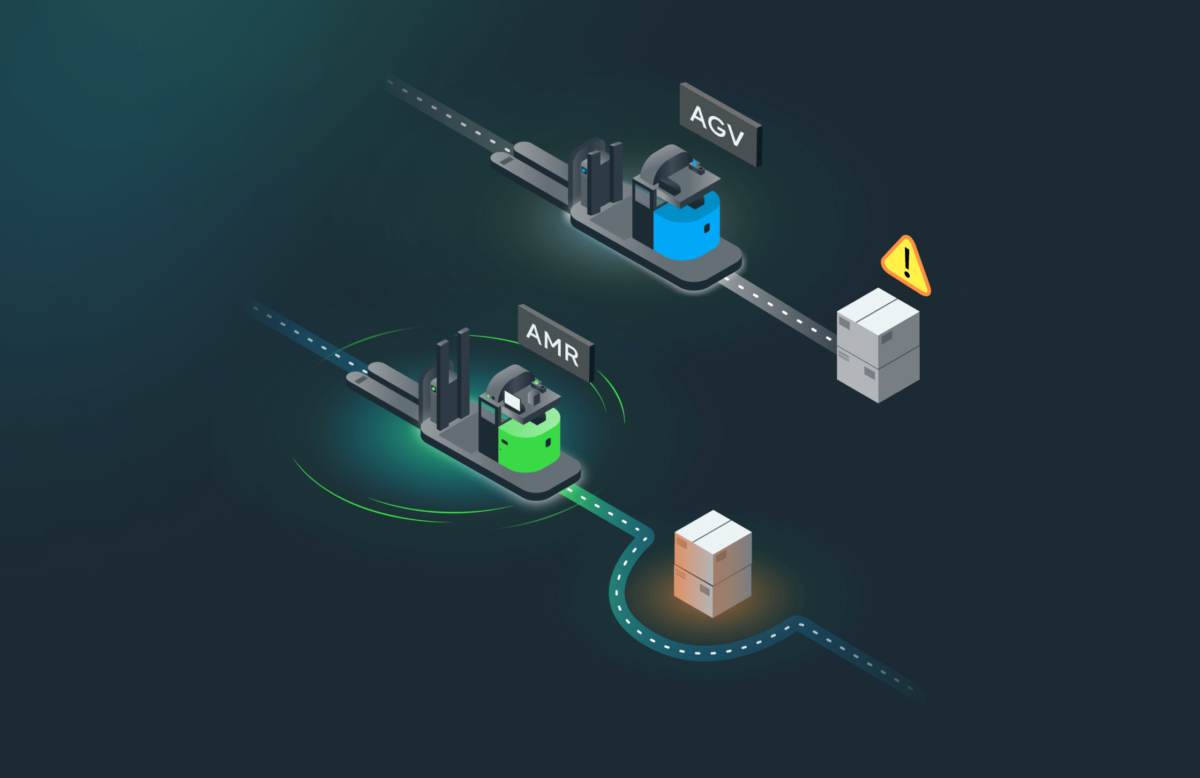

Before probing into the kinds of AGVs used by most warehouses and factories, let’s differentiate between AGVs and Autonomous Mobile Robots (AMRs).

The automatic guided vehicle is an older technology that has morphed into the AMR. The terminology can be confusing because although AMRs are a more modern form of AGV, and the two terms really represent different things, people will often use the terms interchangeably. Technically, that’s valid, even though the two ideas have come to designate distinct concepts.

The route of an AGV is historically defined by physical infrastructure such as:

- laser targets mounted to racks and columns

- colored or magnetic tape on the floor

- visual markers placed on

- walls

- shelves

- stationary equipment,

- wires embedded into the flooring.

Some modern AGVs use more modern, infrastructure-free navigation such as lidar or vision. However, the defining characteristic of AGVs are that they always travel along a predetermined pathway. If something gets in their way, the AGV must stop and call for help. It cannot deviate from its prescribed path.

On the other hand, an Autonomous Mobile Robot (AMR) carries a facility map in its computer memory. It needs no particular infrastructure to navigate. Once assigned a destination, the AMR can choose its own way of getting there. Most often, an AMR will choose the shortest route. But if an obstacle blocks its way, the AMR can swerve around it. An AMR can also plan out and travel via an entirely different route if it needs to avoid an obstruction. The AMR has a navigation system made up of multiple onboard sensors like cameras and lasers that enable it to be aware of its environment so that it can safely maneuver.

For more on the distinctions between AGVs and AMRs, see the white paper: Everything you need to know about AMR and AGV Navigation and why it matters.

Types of automatic guided vehicles

AGVs come in all shapes and sizes, from small, low-slung, lightweight carts to massive tractors carrying hundreds of thousands of pounds – and everything in between. Here, we look at the most commonly used automatic guided vehicles for the warehouse and factory.

Deck-load or unit-load AGVs

Videos of rectangular, orange hockey puck-style AGVs in an Amazon fulfillment center sliding underneath yellow shelving units have millions of views on YouTube, so many people have seen a deck-load AGV. Sometimes called an “under ride,” this type of AGV has a configurable, flat top for supporting multiple types of payloads / attachments, and most often positions itself under its load and lifts it up slightly before carrying it to the destination.

Automatic tow tractors

As the name suggests, this kind of AGV functions like a railroad engine, towing one or several carts behind it. Also called tugger AGVs, these automated tow tractors can transport substantial amounts of cargo efficiently.

Robotic forklifts

Among the most versatile and often-used industrial vehicles, the manually driven, powered forklift is on its way to being replaced by robotic forklifts. Modern, automated forklift trucks can not only travel without a driver within a facility, but they can also easily hand off goods to conveyor belts, wrappers, and pallet racks.

Closely related but optimized for longer ground-level hauls, the Automated Pallet Truck (APT) is used for cross-docking and sortation, as well as picking and put-away tasks.

Automatic forklifts dramatically reduce labor and increase safety.

Automated pallet jack

For those in-between jobs, the manual pallet jack is a go-to tool. The modern, automated form is a collaborative robot that increases productivity and throughput. Most often used for those workflows that don’t seem to fit into other categories, the co-bot pallet jack handles finished goods and work-in-process products. Designed for ease of movement within constrained spaces, the automated pallet jack excels at micro workflows like waste disposal, empty pallet transport, and other similar, low-value-added tasks.

Internal simulations and field tests by Vecna Robotics show an automatic pallet jack can improve throughput by 45% as compared to manual methods.

What does the future hold for your logistics?

A new generation of Automatic Guided Vehicles is revolutionizing the material handling industry and helping to streamline day-to-day operations. The era unfolding before us features Autonomous Mobile Robots that offer enhanced flexibility, capability, and throughput when compared to traditional methods. If you’re looking for ways to automate your material handling operations, reach out to an experienced, knowledgeable Vecna representative who can help you determine what kinds of automatic guided vehicles – think autonomous mobile robots – will give the best return on investment for your application.

If you’re ready to get started with an initial assessment, contact us to set up an appointment with a Vecna Robotics automation expert.