High Capacity AMRs and AGVs have a singular, shared primary function: to move pallets efficiently. However, when it comes to pallet handling, not all robots are not created equal. When automating, it is important to look at the capabilities of each autonomous vehicle and consider the true advantages of AMRs over AGVs in increasing warehouse efficiency and material handling performance.

Pallet Pickup Capabilities of Autonomous Vehicles

A key example that highlights these differences is the way AMR and AGV forklifts approach pallet pickup. Traditional AGV forklifts cannot pick up pallets and require a human to manually load the pallet onto the forks. Advanced AGVs can independently pick pallets, but come with significant restraints on pallet detection. Across the board, AGVs need precise staging and can only move a limited range of pallets. AMRs are an all-around, robust and flexible automated pallet handling solution – reducing direct worker involvement and offering higher-level capabilities that are critical to operational warehouse efficiency.

Advanced AMR Pallet Detection

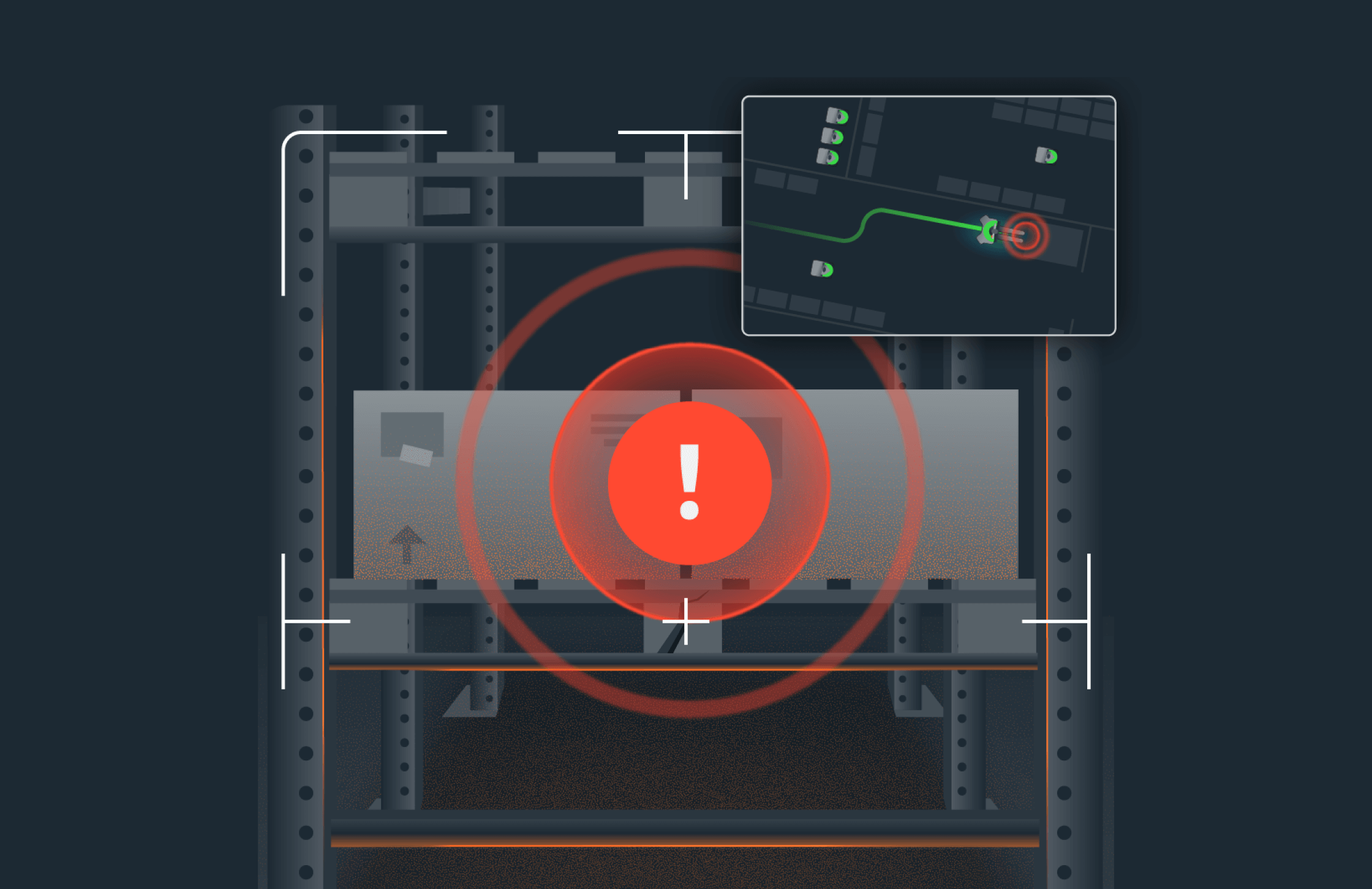

Perhaps the most important distinction to be made is that of AMR and AGV pallet detection abilities. AGVs navigate to a location where they think their assigned pallet should be. If the pallet is not placed in just the right spot with precise alignment, the AGV will attempt to pick up the pallet, fail, and then wait for a human to assist. Warehouses are notoriously fast-paced and dynamic environments, where goods and people are moving quickly. The likelihood that a pallet is placed askew in the drop-zone is fairly high, meaning that the operational warehouse efficiency gains you expect from introducing robots will be diminished with AGVs.

AMRs use intelligent pallet detection. While AGVs will only drive to one exact location to find a pallet, AMRs will use sensory data to determine the pallet is in place before they attempt to pick it up. If the chosen pallet is not in the correct drop zone, the AMR will not attempt, fail and wait for assistance. Instead, it will sense this and continue to search in likely pallet drop-off locations nearby. This approach unlocks massive efficiency gains as it allows operators to work quickly and with less specificity, as AMRs will forgive imperfect drop-offs as long as the pallet is nearby. Most importantly, AMRs allow operators the freedom to work without interruption with fewer stops and calls for assistance. A pallet mover robot that can adapt to a realistic, ever-changing environment will ultimately provide the most flexibility and the best benefits.

AMRs Maximize Warehouse Efficiency with Task Accuracy and Superior Navigation

Not only do AMRs have superior localization and obstacle avoidance, but they excel in task competency as well. With combined intelligence and industry-leading skills in these categories as well as pallet detection, AMRs offer the most benefits in all applications. In all categories, AMRs such as Vecna Robotics’ Pallet Truck, Fork Truck and Tugger have the better navigation systems and execute tasks with greater accuracy. Additionally, Vecna Robotics offers AMRs with AI that can not only excel from the start in variable conditions, but will improve over time – no matter how the floorplan or workflows may shift. With continuous learning and business intelligence tools, operational efficiency will increase and facilities can gain a competitive advantage. This advanced technology maximizes investments in autonomy, and it is best to choose robots with capabilities that best match the needs of your organization.

Navigation and task accuracy are the most important factors towards reaching the highest efficiency gains. Download the full guide to AMR and AGV Navigation here.

Learn more about AMR Obstacle Avoidance and Localization.