Supply chain disruptions have proven to be the “new normal” impacting both warehouse and factory operations and have fundamentally changed how goods are moved worldwide. Since the COVID-19 pandemic started in 2020, warehouses, manufacturers, and consumers have experienced disruptions ranging from the tragic to the absurd. Who could forget the great toilet paper run of March 2020? Or the Ever Givens notorious Suez Canal misadventure in March 2021? No matter the origin of these disruptions, the consequences for businesses, individuals, and entire nations are always costly and occasionally spin out into more significant life-or-death crises.

The pain of supply chain disruptions has been acute and pervasive. Accenture has reported that 75% of companies have had negative or strongly negative impacts on their businesses, with 55% planning to downgrade their growth outlooks. The bad/worse news? These supply chain shocks aren’t going away any time soon. As Gartner reports, “Supply chain disruption is no longer an “if,” nor is it a “when” since it’s both omnipresent and unpredictable at the same time.”

“Supply chain disruption is no longer an “if,” nor is it a “when” since it’s both omnipresent and unpredictable at the same time.”

Gartner

Many companies have begun to make structural changes as this new reality sets in. Mckinsey notes that over the past 12 months, two-thirds of companies have implemented new supply chain risk management practices, with supply chains remaining at the top of the corporate agenda for the third year in a row. However, that same 2021 supply chain pulse survey revealed that despite the progress made, “there remained a significant gap between respondents’ ambition and their action.” This illustrates an urgent need for tangible strategies and actionable plans to bridge this gap. In short, the industry has a long way to go when it comes to building supply chain resilience, and there is an increasing recognition that theoretical planning must translate into real-world solutions.

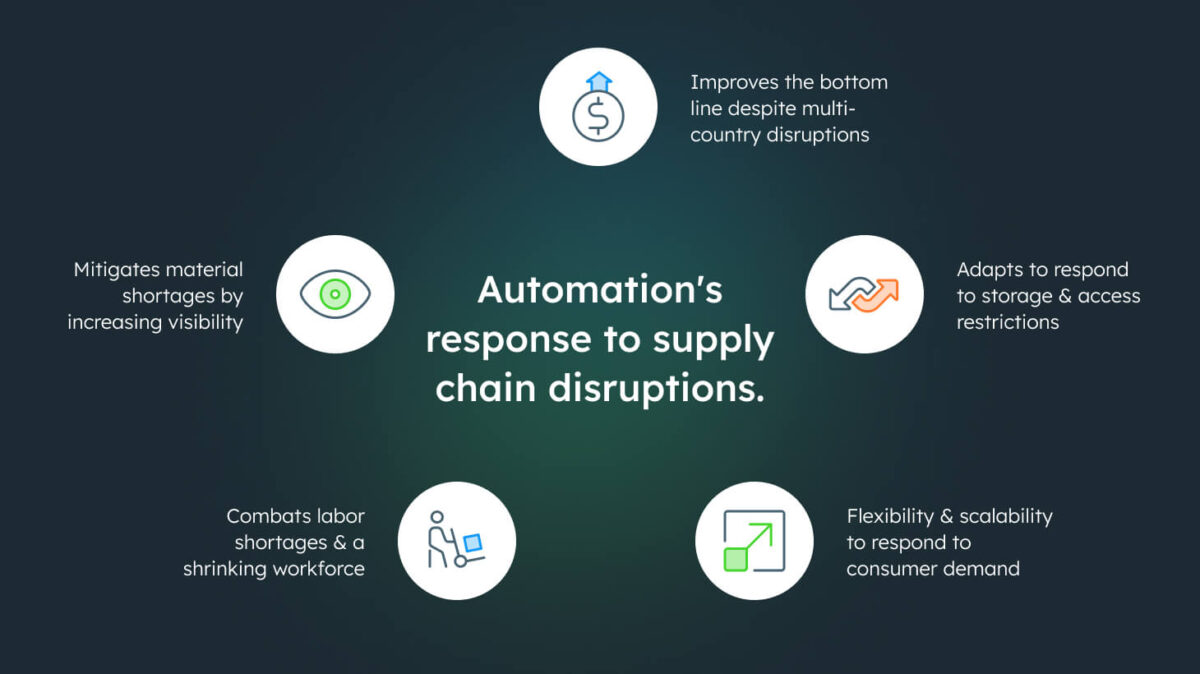

Now for the good news: Help is already here. Innovations in automation can help companies solve their immediate pain while building long-term stability. Even better, this new technology has never been more available (or affordable), and it offers a way to not only respond to current disruptions but also to proactively address future challenges. From enhancing visibility into raw material availability to combating labor shortages, automation presents versatile solutions tailored to modern supply chain complexities. This article will explore how automation can help manufacturers and warehouses respond to 5 of the biggest supply chain disruptions, serving as a critical tool in fostering adaptability and resilience in a rapidly changing business landscape.

1. Automation improves the bottom line in the face of multi-country disruptions

Multi-country supply chain disruptions—where the flow of goods, materials, and services between multiple countries in a supply chain breaks down—are among the most destructive supply chain shocks due to their massive scale and unpredictability. Such disruptions are often rooted in complex geopolitical, economic, and environmental factors that span across nations. Multi-country events like the Pandemic, or the war in Ukraine, have recently exposed the flaw of the decades-long push to globalize supply chains. This global interconnectedness, while promoting efficiency and cost reduction, also leaves systems highly vulnerable, resulting in magnified impacts when disruptions occur. The ripple effects can spread quickly, leaving businesses scrambling to adjust their operations.

Flexible Automation has emerged as a viable solution to alleviate some of these challenges. By driving enhanced efficiency via consistent takt and cycle times, even in rapidly changing circumstances, automation takes some of the “ouch” out of multi-country disruptions. It offers agility and responsiveness that traditional systems might lack. Automation can also help businesses looking to avoid future multi-country disruptions by enhancing reshoring or nearshoring strategies. By bringing production closer to consumption markets, companies can reduce dependency on vulnerable global networks. Autonomous mobile robots (AMRs) such as co-bots drive higher throughput in the smaller plants typical to near/reshoring destinations. This not only provides closer access to local markets but also builds a more resilient and adaptable supply chain structure capable of withstanding the multifaceted challenges of multi-country disruptions.

Read more

Did Someone Say Co-Bots?2. Automation adapts to respond to storage and access restrictions

During the pandemic, many warehouses and manufacturers had to shut down parts of their operations due to outbreaks or rapidly reorganize their floors due to social distancing mandates. Whether from contamination, natural disasters, or regulatory requirements, these types of storage and access restrictions—which render parts of normal operations inaccessible—stymie productivity and strangle a company’s throughput.

Automation’s role in adapting to such unexpected changes has become increasingly pivotal. Unlike traditional operations where equipment is purpose-built for specific tasks and processes, flexible automation adapts to fit new workflows, layout changes, and lines—eliminating lengthy changeover times. Much of this rapid repurposing and reconfiguration is powered by over-the-air software updates to enable even greater agility.

Automation’s adaptability to storage and access restrictions isn’t merely a reactive measure; it’s an essential part of building resilient systems. Advanced robotics and autonomous systems are equipped with sensors, AI, and machine learning algorithms that allow them to continuously learn and adapt to changing environments. These technologies enable the automation system to detect storage restrictions or access limitations in real time and instantly reroute or reassign tasks. This adaptability ensures uninterrupted operations even in the face of sudden changes.

Moreover, automation platforms often come with remote monitoring and control capabilities. This feature allows for quick adjustments to workflows from a centralized location, reducing the need for manual intervention. For example, if a section of the warehouse becomes inaccessible due to contamination, automated systems can be swiftly reprogrammed to work around the affected area. These real-time adjustments minimize delays and maintain efficiency.

3. Automation enables flexibility and scalability to respond to volatile consumer demand

Just what is up with today’s moody consumers? One day everyone is climbing over each other for a bottle of hand sanitizer, and the next, they’re playing tug-of-war over bicycles. Material handlers must meet the high demands and changing preferences of consumers, who have become accustomed to quick and easy access to products through direct-to-consumer (DTC) and e-commerce channels. This volatility in demand requires an unprecedented level of flexibility and adaptability in production and distribution.

Material handlers can use flexible automation to rapidly ramp production up and down or produce a higher mix of products to overcome this volatile demand. Unlike fixed infrastructure, flexible automation systems allow for modular floor layouts, can quickly recalculate mobile robot paths, and are installed in a matter of days or weeks. These features are vital in an era where consumer trends can shift overnight, requiring a complete overhaul of production lines.

Robots as a Service options further enhance the flexibility of automation, allowing companies to get better ROI and scale up or down faster as robots are paid for on a subscription basis rather than as capital hardware. This provides a cost-effective means to adapt to fluctuating demand without significant upfront investment.

The scalability and flexibility enabled by automation aren’t just confined to production but extend to inventory management, order processing, and delivery as well. With integrated AI and machine learning algorithms, automation systems can predict shifts in consumer behavior, allowing for proactive adjustments to inventory levels and manufacturing schedules. This predictive ability helps in preempting market changes, positioning companies to respond effectively to sudden spikes or drops in demand.

Automation also goes a long way in fostering collaboration between different parts of the supply chain, creating a cohesive system that reacts in unison to market changes. By unifying data and operations, automation provides a seamless flow of information that enhances real-time decision-making.

4. Automation combats labor shortages and a shrinking workforce

A swirling mass of trends from “the great resignation” to shifting demographics and wage inflation have converged to create an unprecedented labor shortage crisis—leading to a record 490,000,000 shortfall in laborers for warehouses and transportation companies in July 2021. Because most operations are still heavily reliant on labor-intensive technology, this deficit has heavily impeded the flow of materials, leading to lower productivity and significant disruptions. The situation is further exacerbated by the aging workforce and increased competition for skilled labor across various industries.

In response to this critical labor shortage, automation has emerged as a vital tool to bridge the gap. Eliminating tedious tasks with the help of automation technologies like AMRs and co-bots gives a smaller labor force a much-needed boost, increasing efficiency by up to 85% compared to just labor alone. This is especially crucial as the shrinking workforce requires existing employees to cover more ground and perform diverse roles.

And it’s not just about productivity—a recent survey of executives found that automation can improve labor retention as well, with a staggering 85% believing that automating specific tasks will allow their employees to focus on more stimulating and enjoyable work. By reducing the manual and repetitive aspects of work, automation enhances job satisfaction, making it easier to attract and retain talent in a competitive market. It also plays a key role in making the workplace a safer environment, minimizing physical strain, and reducing the risk of injuries.

Automation also allows for continuous operations, minimizing the impact of employee absenteeism or turnover. With robots and automated systems able to function 24/7, the dependency on a large workforce is reduced, and companies can maintain consistent production levels even amidst fluctuating staffing.

5. Automation mitigates raw material shortages and inflation by increasing visibility

have put a squeeze on the usual flow of raw materials and products that North American companies have become reliant on. As a result, supply chains are facing formidable challenges as companies struggle to stabilize their supply in the face of soaring prices and severe shortages of materials. The inflationary pressures and the scarcity of essential raw materials have made operational efficiency and real-time visibility into the supply chain more critical than ever.

Automation can give companies a clearer view of their inventory levels, helping them avoid shortages. Automated systems such as robots, coupled with advanced tracking and data analytics, can monitor every part and assembly down to the smallest component and process stage. This granular visibility is crucial for effective decision-making and resource allocation. The data enables operations to see what they can produce daily or even hourly, allowing for precise planning and execution. If a disruption occurs in the supply chain (e.g., a shortage of parts), the company can quickly redirect efforts towards producing parts with available supplies, minimizing downtime caused by waiting for the next supply delivery.

This level of detail in inventory tracking also allows companies to identify trends and forecast future shortages, enabling proactive measures to secure alternative sources or adjust production schedules. The increased visibility also supports better negotiation with suppliers, as real-time data on inventory and consumption rates can lead to more favorable purchasing terms, thereby helping in inflation management.

In essence, automation’s role in enhancing visibility into raw material availability goes beyond just real-time tracking. It’s a comprehensive approach that integrates intelligent monitoring, predictive analytics, and agile response mechanisms. By enabling companies to see, understand, and act on their supply chain conditions, automation serves as a powerful tool to mitigate the challenges of raw material shortages and inflation, fostering resilience and ensuring uninterrupted operations in a complex and ever-changing global landscape.

Though it’s pretty unlikely we’ll see manufacturers and warehouses completely sever ties with global suppliers, automation can give material handlers access to backup strategies that bring them closer to their customers and unlock new productivity and flexibility benefits. This includes creating agile manufacturing processes, enhancing communication with local suppliers, optimizing warehousing strategies, and developing responsive transportation networks. By leveraging automation, businesses can maintain more efficient control over their supply chains, mitigating the effects of international disruptions, inflation, and material shortages.

In the long run, this comprehensive and proactive approach to integrating automation in supply chain management will give many companies a competitive edge over those that adopt a “wait and see” approach to supply chain disruptions. By fostering adaptability, efficiency, and resilience, automation stands as a key strategic asset for modern businesses navigating an increasingly complex and uncertain global economy.

To learn more about how flexible automation helps companies adapt to disruptions, diversify their supplier base, use data to maintain consistent inventory levels and avoid downtime, retain their workforce, and improve quality, check out “Shock and Yaw: How Material Handling Robotics Can Drive Supply Chain Resiliency.”

If you’re ready to get started with an initial assessment, contact us to set up an appointment with a Vecna Robotics automation expert.