Understanding Cobots: How Collaborative Robots Are Transforming Industries

In the rapidly evolving world of automation, collaborative robots, or cobots, aren’t just changing the game—they’re rewriting the rules. Designed to be teammates rather than just tools, cobots are revolutionizing material handling with their ability to work side by side with humans, enhancing productivity, safety, and ingenuity across the board. It turns out that there’s a lot to learn about these friendly little partners in productivity, but those who truly understand their strengths will also get to benefit from their remarkable strengths. In this crash course to cobots, we’ll unpack what sets them apart from traditional robots, delve into their problem-solving prowess, and highlight their role in industries craving efficiency and safety. We’ll spotlight different cobot types and the trailblazers leading the cobot innovation, culminating in an introduction to Vecna Robotics’ pioneering cobot pallet jack, a game-changer poised to transform material handling.

What are Cobots?

A collaborative robot, or cobot, is a type of robot designed specifically to work alongside human operators in a shared workspace. Unlike traditional robots, which are typically isolated from human workers due to safety concerns, cobots are engineered to interact safely with humans, often directly assisting in tasks or complementing human efforts. Cobots are characterized by their user-friendly design, flexibility, and ability to be quickly deployed in various tasks without extensive programming or setup.

Cobots are not meant to replace human workers but to augment their capabilities. They can take over repetitive, dangerous, or ergonomically challenging tasks, allowing human workers to focus on more complex and creative aspects of their jobs. This collaborative nature makes cobots an ideal solution for small and medium-sized enterprises (SMEs) that may not have the resources to implement fully automated systems but still wish to increase efficiency and reduce labor costs.

Cobots vs. Robots: the differences and strengths

The primary difference between cobots and traditional industrial robots lies in their intended use and operational environments. Traditional robots are typically large, powerful machines designed to perform tasks autonomously in isolated areas, away from human workers. These robots are often used in manufacturing processes such as welding, painting, or assembly, where their speed, precision, and strength are invaluable. However, due to their size and potential for harm, traditional robots are usually enclosed within safety cages to prevent accidental human contact.

In contrast, cobots are designed with safety and collaboration in mind. They are generally smaller, lighter, and equipped with advanced sensors and software that allow them to detect and respond to the presence of humans in their workspace. Cobots can slow down, stop, or even reverse their actions if they sense an obstacle or person in their path. This makes them inherently safer and more adaptable to environments where humans and robots need to work together closely.

Another key difference is the ease of programming and deployment. Traditional robots often require specialized knowledge and significant time to program and integrate into a production line. Cobots, on the other hand, are designed to be more user-friendly, with intuitive interfaces that allow even non-experts to set up and program the robots with minimal training. This flexibility enables businesses to deploy cobots quickly and adjust them as needed for different tasks.

What Problems Are Cobots Solving?

Cobots are addressing a variety of challenges across multiple industries, from manufacturing to healthcare. One of the primary problems they solve is the shortage of skilled labor. In many industries, finding and retaining skilled workers is increasingly difficult, leading to production bottlenecks and increased labor costs. Cobots can help fill this gap by taking on tasks that do not require advanced skills, allowing human workers to focus on more specialized and value-added activities.

For example, in the automotive industry, cobots are used to perform repetitive tasks such as assembly line work, where precision and consistency are crucial. This reduces the strain on human workers, who might otherwise suffer from repetitive strain injuries or fatigue. In the electronics industry, cobots are used for tasks like soldering and assembling delicate components, where human error could lead to costly defects. By taking over these tasks, cobots help ensure higher quality and consistency in the final products.

Cobots are also solving ergonomic challenges. In sectors like logistics and warehousing, workers are often required to lift and move heavy objects, which can lead to injuries and long-term health issues. Cobots designed for material handling can assist by lifting and transporting goods, reducing the physical burden on workers and minimizing the risk of injury.

In healthcare, cobots are being used to assist with tasks such as patient handling and surgery, where precision and safety are paramount. For instance, surgical cobots can provide steady, precise movements during operations, reducing the risk of human error and improving patient outcomes. In rehabilitation, cobots can help patients regain mobility by providing consistent, controlled support during physical therapy exercises.

How do Collaborative Robots Improve Safety?

Safety is a paramount concern when it comes to the design and implementation of cobots. Unlike traditional industrial robots, which require safety cages and extensive safety protocols to prevent accidents, cobots are built with safety features that allow them to operate in close proximity to humans without posing a significant risk.

One of the primary safety features of cobots is their ability to sense and respond to their environment. Cobots are equipped with advanced sensors, such as force/torque sensors, 3D cameras, and LIDAR systems, that enable them to detect obstacles and human presence in real-time. These sensors allow cobots to adjust their speed, force, and trajectory automatically, ensuring that they can stop or slow down if they come into contact with a human or another object.

In addition to sensory capabilities, cobots are designed with compliance and force-limiting technology. This means that if a cobot encounters resistance beyond a certain threshold—such as bumping into a human—it will either stop immediately or reverse its movement. This feature is crucial for preventing injuries in environments where humans and robots work side by side.

Moreover, cobots often have rounded edges, soft materials, and lightweight structures that further reduce the risk of injury. The programming interfaces of cobots also include safety protocols, such as defining safe zones, setting speed limits, and restricting force application, which can be customized based on the specific work environment and tasks.

These safety features make cobots ideal for collaborative environments, where the focus is on enhancing human productivity without compromising safety.

What Are the Benefits of Cobots?

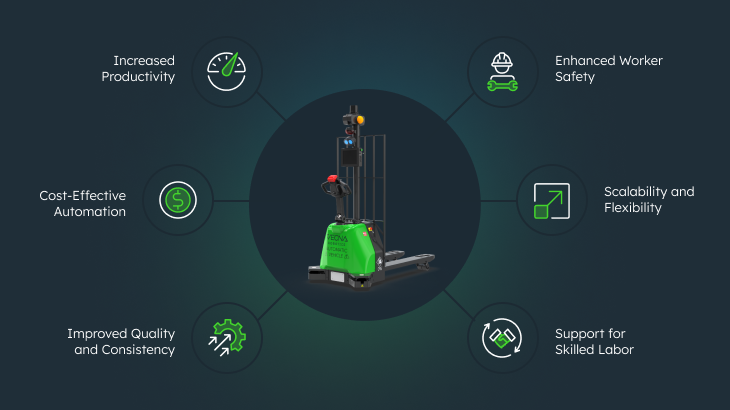

The rise of cobots brings a myriad of benefits to industries, businesses, and workers alike. Here are some of the key advantages:

- Increased Productivity: Cobots can work alongside human workers to increase overall productivity. By taking on repetitive, mundane, or physically demanding tasks, cobots free up human workers to focus on more complex and value-added activities, leading to higher efficiency and output.

- Cost-Effective Automation: Cobots offer a more affordable entry point into automation, especially for SMEs. They require less initial investment compared to traditional robots, and their ease of programming and reconfiguration means that they can be quickly adapted to new tasks without significant downtime or costs.

- Improved Quality and Consistency: Cobots excel at performing repetitive tasks with high precision, reducing the risk of human error. This leads to improved product quality and consistency, which is particularly important in industries like electronics, automotive, and pharmaceuticals.

- Enhanced Worker Safety: By taking on dangerous or ergonomically challenging tasks, cobots reduce the risk of workplace injuries. This not only protects workers but also reduces costs associated with worker compensation claims and lost productivity due to injuries.

- Scalability and Flexibility: Cobots can be easily scaled and reprogrammed to meet changing production needs. This flexibility makes them ideal for businesses that need to adapt quickly to market demands or introduce new products.

- Support for Skilled Labor: Cobots help address the shortage of skilled labor by augmenting the capabilities of existing workers. They can assist with tasks that require precision and consistency, allowing skilled workers to focus on more strategic and creative aspects of their jobs.

What Are the Different Types of Cobots and Who Are the Industry Leaders?

Cobots come in various forms, each designed for specific types of tasks and industries. Here are some of the most common types of cobots:

- Articulated Cobots: These cobots have multiple joints, similar to a human arm, which allows for a wide range of motion and flexibility. They are commonly used in tasks that require precision, such as assembly, welding, and painting.

- SCARA Cobots: Selective Compliance Articulated Robot Arm (SCARA) cobots are designed for tasks that require high speed and precision in a horizontal plane. They are often used in electronics assembly, pick-and-place operations, and packaging.

- Delta Cobots: Delta cobots have a spider-like structure with multiple arms connected to a common base. They are known for their high speed and are typically used in applications such as packaging, sorting, and material handling.

- Cartesian Cobots: Also known as linear or gantry robots, Cartesian cobots operate on three linear axes (X, Y, and Z). They are used for tasks that require precise linear movements, such as CNC machining and 3D printing.

- Mobile Cobots: These are autonomous mobile robots (AMRs) equipped with collaborative features, allowing them to navigate dynamic environments and assist with tasks such as material transport, inspection, and inventory management.

Industry leaders in the cobot space include companies such as Universal Robots, FANUC, KUKA, ABB, and Yaskawa. Universal Robots is often credited with pioneering the cobot market, offering a range of user-friendly and versatile cobots that are widely used across industries. FANUC and KUKA are known for their advanced robotics technology and offer cobots with high payload capacities and precision. ABB and Yaskawa are also prominent players, providing cobots with cutting-edge safety features and ease of integration.

7 Industries Using Cobots to Supercharge Safety, Productivity, and Precision

Cobots are being deployed across a wide range of industries, transforming workflows and improving efficiency. Some of the key industries using cobots include:

- Manufacturing: In manufacturing, cobots are used for tasks such as assembly, welding, painting, and quality inspection. They help improve production speed, accuracy, and consistency while reducing the risk of human error.

- Automotive: The automotive industry uses cobots for assembly line tasks, such as fitting parts, tightening screws, and inspecting components. Cobots help enhance precision and reduce production times, contributing to higher overall vehicle quality.

- Electronics: In the electronics industry, cobots are used for tasks like soldering, assembling small components, and testing finished products. Their ability to handle delicate parts with precision makes them ideal for this sector.

- Healthcare: Cobots in healthcare assist with surgeries, patient handling, and rehabilitation exercises. They provide precision, reduce the risk of human error, and support healthcare workers in delivering better patient outcomes.

- Logistics and Warehousing: Cobots are used in logistics for picking, packing, sorting, and transporting goods within warehouses. They help optimize inventory management, reduce handling times, and minimize the risk of injuries from heavy lifting.

- Food and Beverage: In the food and beverage industry, cobots assist with packaging, palletizing, and quality control. Their ability to operate in clean environments and handle products delicately is essential for maintaining food safety standards.

- Pharmaceuticals: The pharmaceutical industry uses cobots for tasks such as drug dispensing, packaging, and lab automation. Cobots help ensure precision and compliance with stringent industry regulations.

How Vecna Robotic’s Industry’s First Cobot Pallet Jack is Changing the Material Handling Game

Vecna Robotics, a leader in autonomous mobile robots and workflow orchestration, has introduced the industry’s first cobot pallet jack—a significant advancement in material handling technology. The Vecna Cobot Pallet Jack is designed to automate the movement of pallets within warehouses and distribution centers, targeting workflows that involve repetitive, labor-intensive tasks.

This cobot pallet jack is unique in its ability to operate safely alongside human workers while automating pallet transportation. It is equipped with advanced sensors and navigation technology that allow it to navigate complex environments, avoiding obstacles and humans, and adjusting its path in real-time. Unlike traditional automated guided vehicles (AGVs), which require predefined paths and infrastructure modifications, the Vecna Cobot Pallet Jack can operate in dynamic environments without the need for extensive setup.

The Vecna Cobot Pallet Jack targets workflows such as pallet staging, cross-docking, and order fulfillment, where pallets need to be moved quickly and efficiently. Its ability to work collaboratively with human workers means that it can be easily integrated into existing operations without disrupting workflow. Additionally, it is designed to handle variations in pallet size and weight, making it a versatile solution for different industries.

What sets the Vecna Cobot Pallet Jack apart is its combination of safety, flexibility, and ease of integration. It can be deployed quickly without significant changes to the existing infrastructure, and its user-friendly interface allows operators to set up and manage the cobot with minimal training. This makes it an ideal solution for companies looking to enhance productivity, reduce labor costs, and improve worker safety.

Cobots are transforming the landscape of industrial automation, offering a flexible, safe, and cost-effective solution for businesses across various sectors. From manufacturing to healthcare, cobots are helping companies overcome challenges related to labor shortages, quality control, and workplace safety. With industry leaders like Universal Robots, FANUC, and Vecna Robotics driving innovation, the future of cobots looks promising. The introduction of the Vecna Cobot Pallet Jack exemplifies the potential of cobots to revolutionize material handling, providing a glimpse into a future where humans and robots work seamlessly together to achieve new levels of productivity and efficiency. As cobots continue to evolve, their impact on industry will only grow, ushering in a new era of collaborative automation.