Palletizing robots are automated systems that are designed to efficiently stack and organize products onto pallets for storage and transport. These robots typically use advanced sensors, cameras, and machine learning algorithms to accurately identify and manipulate products and can operate at a much faster rate than manual labor.

Industries and applications

The utility of palletizing robots stretches across a diverse industrial landscape, testament to their adaptability, efficiency and ability to handle a wide range of products. As global industries continue to grow in scale and complexity, the demand for seamless, efficient, and rapid processes is more pressing than ever. Palletizing robots rise to this challenge, fitting seamlessly into various sectors, each with its own set of unique requirements.

Within manufacturing, for example, where production lines churn out thousands of units daily, these robots are invaluable. Their precision allows them to pick components or finished products from conveyor belts and stack them meticulously, ensuring optimal use of space and reducing the risk of damage. This is especially crucial when dealing with fragile or high-value items, where errors can have significant financial implications.

In logistics hubs and distribution centers, speed and accuracy are paramount. Palletizing robots streamline the loading and unloading processes, minimizing delays and maximizing throughput. They can be programmed to recognize and handle a myriad of products, adapting their stacking patterns to best fit the cargo’s dimensions and the destination’s requirements.

The food and beverage sector, with its stringent safety and hygiene standards, has particularly benefited from these robotic wonders. The automated nature of these robots minimizes human contact, reducing the risk of contamination. Whether it’s arranging boxes of confectionery, sorting diverse bottles of beverages, or grouping frozen goods, these robots can be customized to operate in varied environments, including refrigerated spaces. Their ability to handle items gently ensures that delicate products like pastries or glass bottles remain intact and undamaged.

Mechanical structure of palletizing robots

The foundation of a palletizing robot is an intricate fusion of mechanics, electronics, and software. At its core, the robotic arm, often an impressive piece of engineering, does the heavy lifting—quite literally. It’s a symphony of interlinked segments, joints, and actuators, each calibrated to perform with utmost precision. These aren’t just crude appendages; they’re designed to mimic and often surpass, the dexterity and range of human motion. This enables the arm to handle goods of varied sizes, shapes, and weights, and stack them on the pallet in the desired configuration.

Anchoring this mechanical marvel is the control unit, often regarded as the robot’s nerve center. More than just sending movement commands, this unit continually processes a deluge of data from an array of sensors and cameras. These sensors help the robot discern its surroundings, detect products, and even make real-time micro-adjustments to its actions to optimize performance or rectify errors. This capability to dynamically react and adjust is crucial in a constantly changing warehouse environment.

But even with such advanced hardware, the robot would be rudderless without its programming system. Think of it as the guiding script for the robotic performance. It’s here that human operators interface with the machine, inputting vital parameters like product dimensions, weight limits, desired pallet patterns, and stacking sequences. Advanced systems may even allow operators to simulate the entire palletizing process, preemptively spotting and rectifying potential issues. Moreover, with evolving software capabilities, robots can learn from past tasks, continuously refining their operations for optimal efficiency.

In essence, a palletizing robot isn’t just a standalone piece of equipment; it’s a harmonized integration of advanced mechanics, cutting-edge electronics, and adaptive software. Together, they ensure that the end-to-end palletizing process is not just automated but is also efficient, accurate, and adaptable to the diverse needs of modern industries.

Benefits of palletizing robots

- One of the key advantages of palletizing robots is their ability to operate at a much faster pace than conventional palletizers. These robots can work 24/7 without breaks and can handle multiple products at once, which significantly increases their efficiency and productivity. Additionally, palletizing robots are also able to handle products that are difficult or dangerous for humans to handle, such as heavy or sharp objects.

- Another advantage of palletizing robots is their ability to handle a wide range of products with different shapes and sizes. The sensors and cameras on the robot allow it to accurately identify the product and manipulate it accordingly. These robots are also able to adapt to changes in the product or packaging, which allows them to handle a wider range of products than traditional manual labor.

- Palletizing robots also improve safety in the workplace. Since they are handling heavy and repetitive tasks, they reduce the risk of injuries to human workers. And their ability to work in harsh environments such as extreme temperatures, dust and noise, increases the safety of the workers who can be in other tasks.

How to match palletizing robots with the right AMR solution

AMRs, or Autonomous Mobile Robots, are a type of robot that can move around a facility independently, without the need for a dedicated track or predefined path. They can be used in conjunction with palletizing robots to automate the movement of products and pallets throughout a facility.

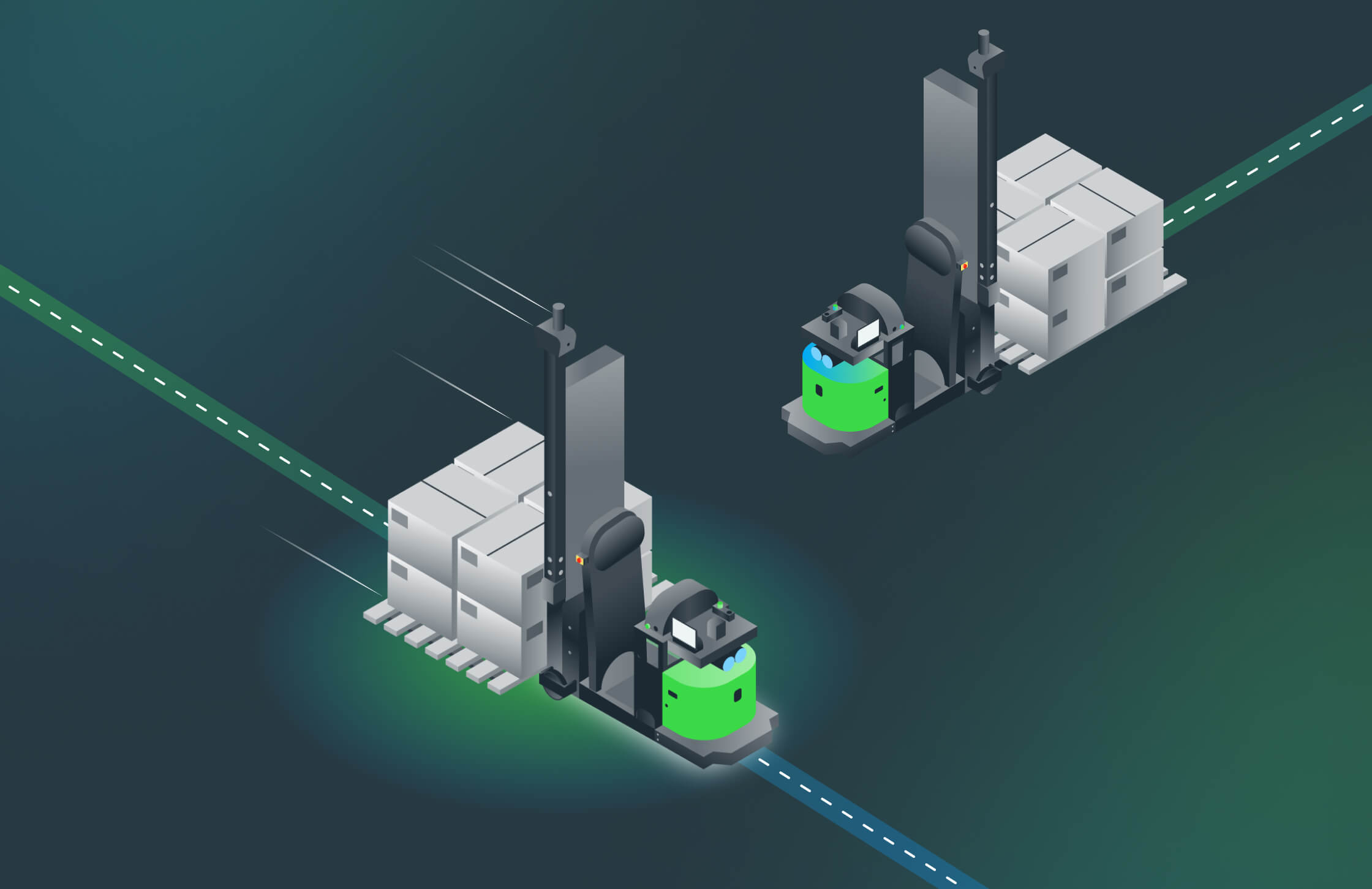

In a typical application, an AMR, or Automated Mobile Robot, serves as an integral component of modern supply chain operations, especially when working in tandem with palletizing robots. Imagine a bustling warehouse filled with products ready for shipment. Instead of relying solely on human effort or static conveyor systems, an AMR springs to action, leveraging its advanced sensors and cameras. Its primary mission: is to identify, locate, and transport the necessary products to the waiting palletizing robot with pinpoint precision.

The palletizing robot, equipped with state-of-the-art sensors and high-resolution cameras, seamlessly identifies each product. It then employs sophisticated algorithms and precise movements to stack them onto a pallet in the most efficient manner. This meticulous, machine-driven process greatly minimizes errors that might occur with manual handling.

Once the pallet is full and organized, the AMR, with its mission not yet complete, retrieves the pallet. The AMR navigates through the maze-like expanse of the warehouse, avoiding obstacles and ensuring safe transport, finally depositing the pallet in a pre-designated storage or shipping zone. Here, larger equipment, such as forklifts, takes over.

But the AMR’s utility doesn’t end with transporting loaded pallets. They can also replenish the palletizing area with empty pallets, ensuring that the palletizing robot has an uninterrupted workflow. This cycle is a testament to the harmonious integration of AMRs and palletizing robots, where each amplifies the other’s strengths.

This collaboration introduces unparalleled flexibility. As warehouses evolve, with changing layouts or product flows, AMRs can be reprogrammed to suit these alterations. This adaptability stands in stark contrast to fixed conveyor systems, which might require considerable time and money to modify. Moreover, a single AMR isn’t restricted to serving just one palletizing robot; it can cater to multiple, simultaneously. This parallel processing substantially compresses the time it takes to palletize goods, boosting operational throughput.

To encapsulate, palletizing robots, backed by the agility of AMRs, are transforming the face of industries. This amalgamation not only enhances efficiency and productivity but also augments safety standards. Manual lifting, a potential hazard, gets minimized. The repetitive strain that workers might face gets reduced. The AMRs and palletizing robots, in their orchestrated dance, represent the zenith of warehouse automation, defining the future of efficient, safe, and productive supply chain operations.

Top 10 Palletizing Robot Solutions in North America as of 2021

- FANUC Robotics: Renowned for their extensive line of robotic solutions, FANUC offers the M410 series, specifically tailored for palletizing tasks. These robots are known for their precision, speed, and durability.

- KUKA Robotics: KUKA offers the KR QUANTEC PA series and other models for palletizing tasks. Their robots have an excellent reputation for reliability and flexibility.

- ABB Robotics: ABB’s IRB 6700 series is one of the most popular solutions for palletizing tasks. ABB robots are recognized for their advanced features and dependability.

- Yaskawa Motoman: Their MPL series, particularly MPL800 and MPL160, are purpose-built for palletizing and depalletizing tasks. Known for their high-speed performance and long life cycles.

- Universal Robots: Their collaborative robot (cobot) arms, such as the UR10, can be used for palletizing when combined with end-of-arm tooling and proper software.

- Kawasaki Robotics: They offer the CP series for palletizing tasks, with robots like CP180L and CP300L. Kawasaki’s robots are designed for heavy payloads and high efficiency.

- Columbia/Okura: A joint venture between Columbia Machine and Okura Yusoki Co., this firm specializes in robotic palletizing solutions. Their robots are efficient and cater to a wide range of industries.

- Stäubli Robotics: Known for their precision, Stäubli’s TX2 series robots can be used for palletizing tasks, especially in environments that require high hygiene standards.

- Bosch Rexroth: Their palletizing solutions combine efficiency with modularity. Their systems can be integrated into existing production lines seamlessly.

- RobotWorx: RobotWorx offers both new and refurbished robotic palletizing solutions from a variety of manufacturers, providing an affordable entry point for many businesses.

Future of Palletizing Robotics

The palletizing sector, which plays a crucial role in the backbone of numerous industries like food and beverages, pharmaceuticals, construction, and more, has undergone profound shifts and metamorphoses, primarily driven by the rapid progress in robotics. Palletizing, a process once dominated by manual labor, now sees the seamless integration of advanced robotic systems designed for efficiency, precision, and reliability.

As we cast our gaze toward the horizon and contemplate what the future holds, it becomes evident that a mosaic of trends and innovations is steering the course of robotic palletizing. These trends are not isolated but are a reflection of broader technological advancements and evolving industry needs. Enhanced machine learning capabilities, for instance, are paving the way for robots that can adapt and optimize their operations in real-time. The increasing push for sustainability and eco-friendliness is driving innovations in robot designs, making them more energy-efficient and reducing their carbon footprint.

Furthermore, as industries expand and diversify, the demand for customizable robotic solutions grows. The palletizing robots of tomorrow will not just be more intelligent but will also be modular, allowing businesses to tailor them to specific needs and operational challenges. The intertwining of these trends and developments paints a promising picture, indicating that the realm of palletizing robotics is poised for a future of continuous evolution and refinement:

- Integration of AI and Machine Learning: AI allows robots to process and analyze large datasets, enabling them to optimize their operations based on real-time feedback. With machine learning, robots can predict anomalies, enhance efficiency, and adapt to changes in real-time.

- Advanced Gripper Technology: Gripper technology will move beyond vacuum and claw grips. Soft robotics, inspired by human and animal physiology, will lead to the development of grippers that can handle a wider range of products without the risk of damage.

- Collaborative Robots (Cobots): Cobots are designed to work alongside humans. These robots are equipped with sensors to ensure human safety. Their adaptability and ease of programming make them ideal for small and medium enterprises.

- Enhanced Flexibility: Palletizing robots will be more versatile, handling multiple SKUs without the need for manual reprogramming or significant downtime. They’ll swiftly switch between tasks based on demand.

- Internet of Things (IoT) Integration: By integrating IoT, palletizing robots will be connected to a broader network, enabling remote monitoring, predictive maintenance, and seamless data exchange with other systems.

- Greater Focus on Sustainability: The drive for sustainable solutions will push manufacturers to design robots that are energy-efficient, have a longer life cycle, and are made from recyclable materials.

- Improved Human-Robot Interface: Interfaces will become more intuitive, allowing workers with minimal training to instruct and program the robots. This democratizes access and ensures more industries can adopt these solutions.

- Increased Mobility: Instead of stationary palletizing robots, there’ll be a move towards mobile robots capable of moving around warehouses, picking products, and then palletizing them.

- Safety Enhancements: With more robots working alongside humans, there’ll be enhanced safety features, including better sensing technologies and quicker response times, ensuring zero accidents.

- Price and Affordability: As technology matures and adoption increases, the cost of palletizing robotic solutions will decrease, making them accessible to a broader range of companies, including small and medium-sized businesses.

- Proliferation in Emerging Markets: As labor costs rise in traditionally low-cost countries, there will be an increased demand for automated palletizing solutions in these regions.

- Customization: Industries will require tailored solutions. Robotic companies will focus on providing customizable robots that can be adapted based on specific industry needs.

In summary, the future of palletizing robotics is dynamic, promising, and central to the evolution of industries. As technology bridges the gap between the digital and physical realms, palletizing robots will emerge as the linchpin of industrial operations, ensuring efficiency, speed, and adaptability. As businesses grapple with fluctuating demands, an uncertain global environment, and the relentless drive for efficiency, robots will stand out not just as tools but as essential partners in growth and progress.

Palletizing robots for your business

Vecna Robotics has a wide range of AMR pallet handling solutions that can help you automate palletizing tasks in your warehouse and improve throughput. For more information about how you can get started, go to our From No Bot to Robot page, or contact us today to schedule a consultation with a warehouse automation expert.