Warehouse robot cost can vary greatly in cost depending on the specific system and its capabilities. Factors that can affect the cost include the size and complexity of the system, the type of robot or automation equipment used, and the level of customization required.

A basic warehouse robot system can cost anywhere from tens of thousands of dollars to several hundred thousand dollars. For example:

- A simple robotic arm used for picking and packing tasks may cost around $50,000 to $100,000.

- Depending on payload and the level of customization Automated Guided Vehicles (AGV) and Autonomous Mobile Robots (AMR) can cost up to $300,000 or more.

- Fully automated warehouse system with multiple robots and advanced features such as computer vision and machine learning capabilities can cost millions of dollars.

Additionally, there are other costs associated with warehouse robot implementation, such as installation and maintenance costs, as well as the cost of any necessary software or programming. Training and educating staff on the robots they’ll be working with and alongside is almost important to factor in and can greatly improve how they feel about the introduction of automation. All these costs can add up and should be taken into consideration when evaluating the total cost of a warehouse robot system.

What’s your ROR?

Return on Robotics (ROR) CalculatorAnother cost to consider is the implementation of warehouse management software which can be integrated with warehouse robots to make the system work more efficiently. This will add extra cost to the total cost of the system, but it can pay off in the long run by increasing productivity, efficiency, and accuracy.

A new way to deploy automation: Robots as a Service (RaaS)

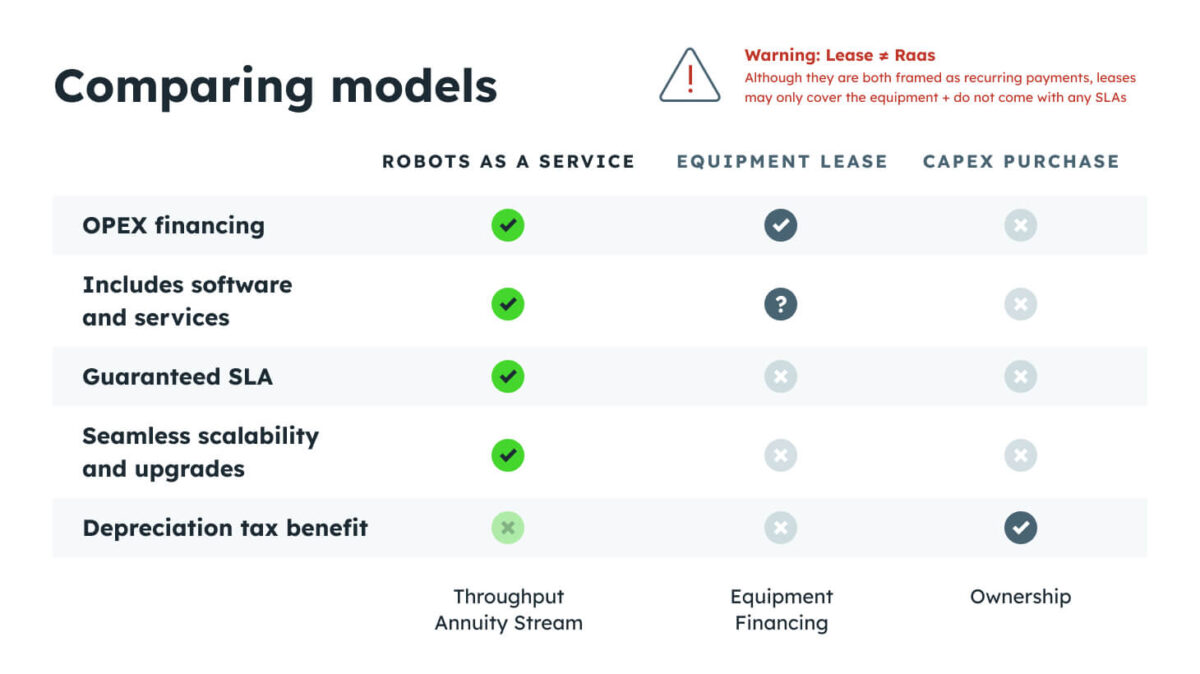

Robot as a Service (RaaS) is much like the familiar Software as a Service (SaaS) pricing models in that it removes high upfront costs and rolls all fees into one, low regularly scheduled payment. This allows customers to realize ROI faster and does not tie up capital with a single lump sum payment.

While there are many benefits to RaaS pricing, the most important is shifting from Capital Expenditure to Operational Expenditure. Rather than having to gain executive-level approvals to purchase assets up-front, RaaS pricing requires a multi-term commitment (e.g. 3-year or 5-year) and a recurring annual payment model. This speeds up decision-making and allows for more efficient use of capital to deploy more robots faster, thereby realizing a measurable return on robotics within the first year. Another benefit of RaaS is that maintenance, support, and services costs are included which means that there are no downstream cost surprises and ensures mission alignment between the automation provider and the warehouse operator.

A Deeper Look at RaaS vs Capex

Traditionally, developing a business case for an automation shift has been difficult. Expensive, fixed asset capital equipment typically involves multiple levels of authorization. RaaS overcomes financial barriers, providing executive leadership with a speedy, low-risk, and cost-effective solution to accelerate automation.

With RaaS as an option, companies can now shift those expenses to the operating side of the house while also increasing production. The most intriguing aspect of RaaS is its near-instant impact on a warehouse company’s production capacity and bottom line. In other words, RaaS can be deployed dynamically to scale up with the needs of the business. When automation is accelerated to support changing business requirements, the ROI is almost instant. Essentially, subscribing to the technology becomes an operational expense, allowing warehouses to reap the benefits rapidly.

The flexibility of RaaS service agreements can also make a significant difference. Agreements can accommodate user fluctuation by allowing customers to stagger payments to hit budget targets, add new equipment subscriptions to an existing agreement to meet immediate needs rapidly, avoid obsolescence through regular software updates and hardware upgrades, and swap out equipment that may not be suitable to new workflows over time.

Customization and personalization at scale have also been concerns for companies. In previous years, automation was in the testing phase and therefore lacked the ability to scale as the business grew. This inability to scale was combined with the integration challenges inherent in existing software and technology already implemented at the facility. Now that automation is utilized in the mainstream, companies are acknowledging the benefits and value of warehouse execution systems and warehouse control systems that automation enables. Also, navigation and perception technology has improved to such a degree that automation solutions can, nearly out of the box deliver highly tuned automation experiences designed for a specific facility without the massive overhead of a non-recurring engineering project.

Our “From No Bot to Robot” Approach

Deploying the appropriate automation solution can feel like venturing into the unknown for many. Few have traversed this path, and amidst varied perspectives on the best method, coupled with concerns of substantial expenses and extended implementations, it might appear daunting.

Presenting Vecna’s “From No Bot to Robot” methodology. These are the 5 essential steps to an automated warehouse, designed to launch you swiftly, reaching scale within a year from your first deployment.

Step 1: Assess

Initially, we delve into the intricacies of your supply chain network to identify potential challenges. By examining factors like inventory status, labor distribution, and more, we can then align these issues with market solutions. With this data in hand, we spotlight a scalable segment of your system where automation can bring maximum value. We craft a tailored use case and choose a solution promising a robust ROI.

The foundation for this is derived from challenges and use cases we’ve recognized as solvable through automation. Commencing with a tried-and-tested solution minimizes uncertainties, assuring you of a successful inaugural deployment.

Step 2: Plan

Post the determination of the right robotic solution for your processes, we evaluate its integration with your staff, infrastructure, and existing systems. Gathering data like CAD blueprints, client routes, travel metrics, and throughput rates, we then ascertain the number of robots required for each workflow.

Subsequent to this, we define success benchmarks with all involved parties and trial the robots in tangible environments to validate they align with expectations. Rather than initiating with a couple of robots, we recommend beginning with at least a trio, facilitating a clearer perspective on robot-human interactions.

However, it’s vital to understand that multiple robots won’t necessarily inflate your anticipated expenses. Thanks to our Robots-as-a-Service (RaaS) framework, you can promptly launch your fleet without hefty initial costs, and scale or modify it according to requirements, all for an affordable annual charge.

Step 3: Deploy

The deployment phase goes beyond mere robot installation. We also equip and familiarize your on-ground team, fostering confidence and encouraging robot utilization. Our roll-out follows a structured six-phase model oriented towards a production use case that adds tangible business value:

- Planning: A preliminary meeting helps align operations concepts and discuss potential IT or WMS integrations.

- Mapping: Post-robot arrival, we employ them to sketch out a floor map.

- Configuration: Network establishment, refining the acquired map, and gearing up for training and installation are done here.

- Installation: We tune and test the robots and conduct multiple training sessions. We also involve the PCC (Pivotal™ command center team), so they understand the process and can easily take over after go-live.

- Staff preparation: On-ground teams are prepped for post-launch processes with mock scenarios and unique training sessions.

- Support: With 24/7 backing and Pivotal™ Insights to examine site metrics, we ensure consistent software upgrades as required.

Robot deployment is intricate; it’s not a mere ‘set and forget’ scenario. Our systematic approach makes the deployment process as smooth as possible and involves customer success teams to help clients understand every aspect. After going live, we have weekly customer calls to ensure everyone is on the same page and everything is running as it should.

Step 4: Learn

During the deployment process, we actively engage all tiers of personnel, fostering transparency and addressing apprehensions. Comprehensive training sessions guarantee that all staff members are proficient with the new technology.

Committing resources to familiarize your team and granting them training opportunities assures their understanding of both personal and organizational advantages. Once robots become operational, we transition to our customer success specialists, ensuring perpetual support and consistent performance reviews.

Step 5: Scale

For organizations looking to automate across various locations or to broaden within a single facility, having a model or pilot site is invaluable. This reference point can guide the automation of other sectors of your network.

We champion the adoption of a unified automation plan from the outset. Not only does this streamline the maiden rollout, but it also assists in sequencing subsequent use case priorities. Moreover, showcasing the pilot site enables unfamiliar stakeholders to witness the robots, reducing skepticism and prepping them for future integrations.

While no one-size-fits-all remedy exists for tackling supply chain disruptions, workforce shortages, and the escalating volume and diversity of goods demanding swift movement and handling, an automated warehouse offers the resilience and efficiency crucial for navigating these challenges.

Overall, the cost of a warehouse robot system can vary greatly depending on the specific system and its capabilities. Basic systems can cost tens of thousands of dollars, while more advanced systems can cost millions of dollars. It’s important to evaluate the cost of not just the initial purchase, but also the ongoing costs of installation, maintenance, and software integration. RaaS pricing models vastly simplify the automation buying experience and free up capital to deploy more automated throughput quickly and avoid any surprise cost as the system matures in years.

Vecna Robotics has a wide range of AMR pallet handling solutions designed to optimize warehouse operations with automation and improve overall throughput. Our solutions are available exclusively via Robots as a Service and allow you to deploy our AMRs for your most demanding warehouse workflows quickly. For more information about how to get your facility started with our automation solutions, go to our From No Bot to Robot page, or contact us today to schedule a consultation with a material handling automation expert.