Warehouse sortation refers to the process of organizing and separating items within a warehouse for efficient storage, retrieval, and shipment. The goal of sortation is to ensure that items are directed to the correct storage locations, and that they are properly tracked and accounted for. Automation plays a significant role in the sortation process by leveraging technology to improve the speed and accuracy of sorting tasks. Let’s take a look at the different types of warehouse sortation systems, how the sortation process works, and what’s next for the future of automation in warehouse sortation.

1. Conveyor systems

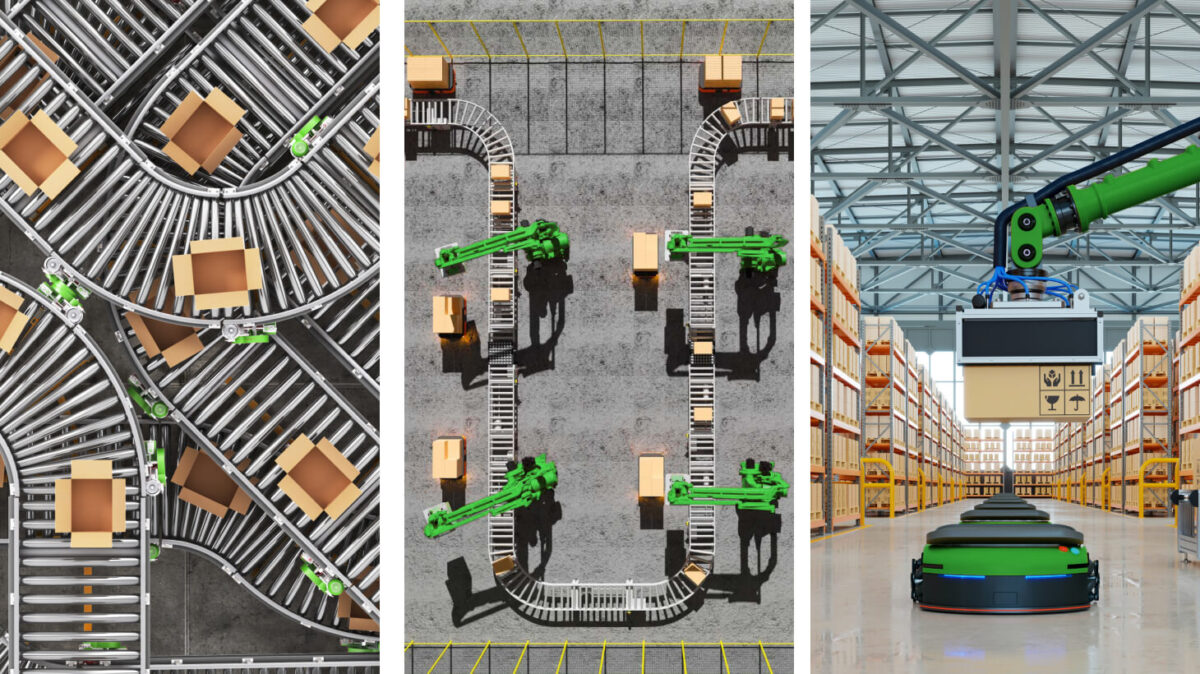

Conveyor systems are one of the most common types of warehouse automation used for sortation. These systems use conveyor belts to move items through the warehouse, allowing them to be sorted and directed to their proper storage locations. Conveyor systems can be configured in a variety of ways, including incline conveyors, decline conveyors, and spiral conveyors, to suit the specific needs of the warehouse.

2. Robotics

Another type of warehouse automation used for sortation is robotics. Robotics can be used for a variety of sorting tasks, including picking and placing items, palletizing and de-palletizing, and even packing and sealing boxes. Robotics can be especially useful in warehouses that handle a high volume of items, or that require precise handling of fragile or valuable items. Different types of autonomous mobile robots (AMR) and autonomous guided vehicles (AGV) play critical roles in automating different types of sortation tasks.

3. Sortation system software

Another important aspect of warehouse automation, sortation system software can be used to track and manage items as they move through the warehouse, including their location, movement history, and status. This can help to ensure that items are directed to the correct storage locations and that they are properly tracked and accounted for.

4. Barcode scanning

Barcode scanning is another common type of warehouse sortation automation. Used to automatically identify and track items as they move through the warehouse, barcode scanning ensures that items are properly sorted and directed to their proper storage locations. This can greatly improve the speed and accuracy of the sorting process, as well as reduce the risk of human error.

5. RFID (Radio-Frequency Identification) technology

RFID (Radio-Frequency Identification) technology allows warehouse workers to quickly and easily track the location and status of items within the warehouse by scanning RFID tags attached to them. This can be especially useful in large warehouses where it can be difficult to manually track the location of items.

6. Machine learning algorithms

The use of machine learning algorithms in warehouse sortation is becoming increasingly popular. These algorithms can be used to optimize sorting processes by analyzing data on item movement and identifying patterns that can help to improve efficiency. This can include predicting demand for certain items, identifying bottlenecks in the sorting process, and even automating the re-ordering of items.

How sortation is used in warehouses

Sortation is used in a number of different processes throughout a warehouse or distribution center to move goods from one place to another.

- Receiving/warehousing: When items arrive at a warehouse or distribution center, they must be received by the facility and then put away in their designated storage areas.

- Sorting: This stage refers to how products are organized and categorized in order to transport them to their final destination.

- Order picking: Sortation aids in order fulfillment by moving ready-to-ship items from storage to picking areas. Completed orders are then transported to the loading dock for distribution.

- Packing: When orders are ready to be distributed, they must be moved to a packing area. Sortation systems can help categorize and prepare items based on programmed criteria.

The future of warehouse sortation

The future of warehouse sortation is likely to see increased use of automation and advanced technology, like the integration of artificial intelligence (AI) and machine learning (ML) into warehouse operations. These technologies can be used to optimize sorting processes by analyzing data on item movement and identifying patterns that can help to improve efficiency. This can include predicting demand for certain items, identifying bottlenecks in the sorting process, and even automating the re-ordering of items. Here’s what we can expect in the coming years.

1. Autonomous mobile robots (AMRs)

AMRs in warehouses will continue to be adopted at significant scale and we will see continued integrations with other warehouse automation technology, such as conveyor systems and ASRS, to increase the overall efficiency of the warehouse.

2. Drones

The use of drones for inventory management and delivery is also being explored as a future trend in warehouse sortation. Drones can be used to quickly and efficiently scan and inventory items within the warehouse, as well as to deliver items to specific locations within the warehouse.

3. Virtual and augmented reality (VR/AR)

The use of VR/AR technology in warehouse sortation is also growing in popularity. VR/AR technology can be used to provide warehouse workers with real-time information and guidance on sorting tasks, as well as to train workers on new tasks and procedures.

Overall, warehouse automation plays a crucial role in the sortation process by improving the speed and accuracy of sorting tasks, reducing the need for human labor, and increasing warehouse efficiency. From the current adoption of conveyor systems, AMR robotics, ASRS, sortation software, barcode scanning, RFID technology and machine learning, to a future filled with increased robotic integration, drones and VR/AR, the use of technology in sortation will continue to provide critical productivity gains in warehouse operations for years to come.

Vecna Robotics has a wide range of pallet handling solutions that can help you automate different sortation tasks in your warehouse and improve throughput. For more information about how you can get started, go to our From No Bot to Robot page, or contact us today to schedule a consultation with a warehouse automation expert.