Wireless Connectivity

If Wi-Fi isn’t working, nothing else will

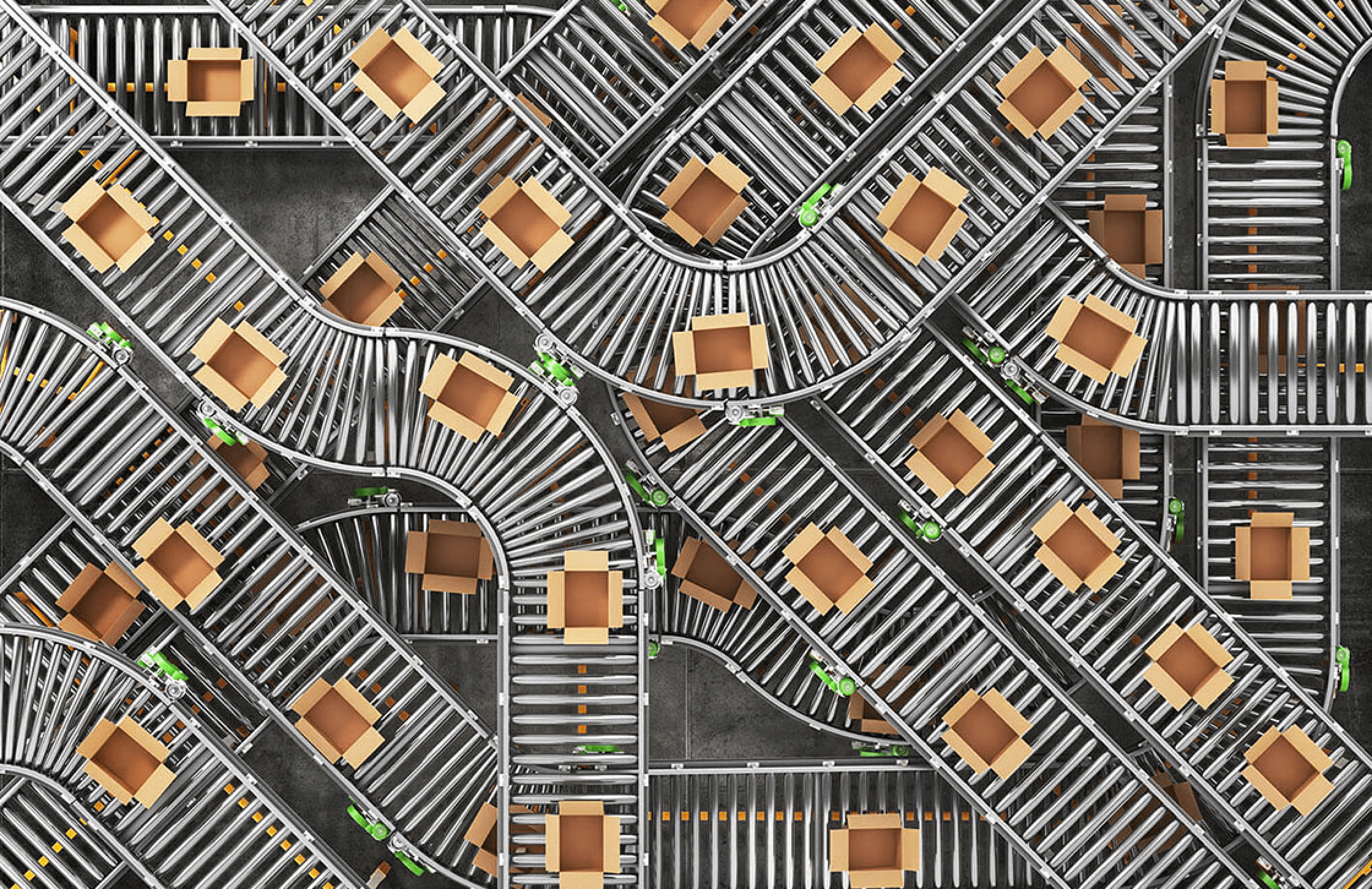

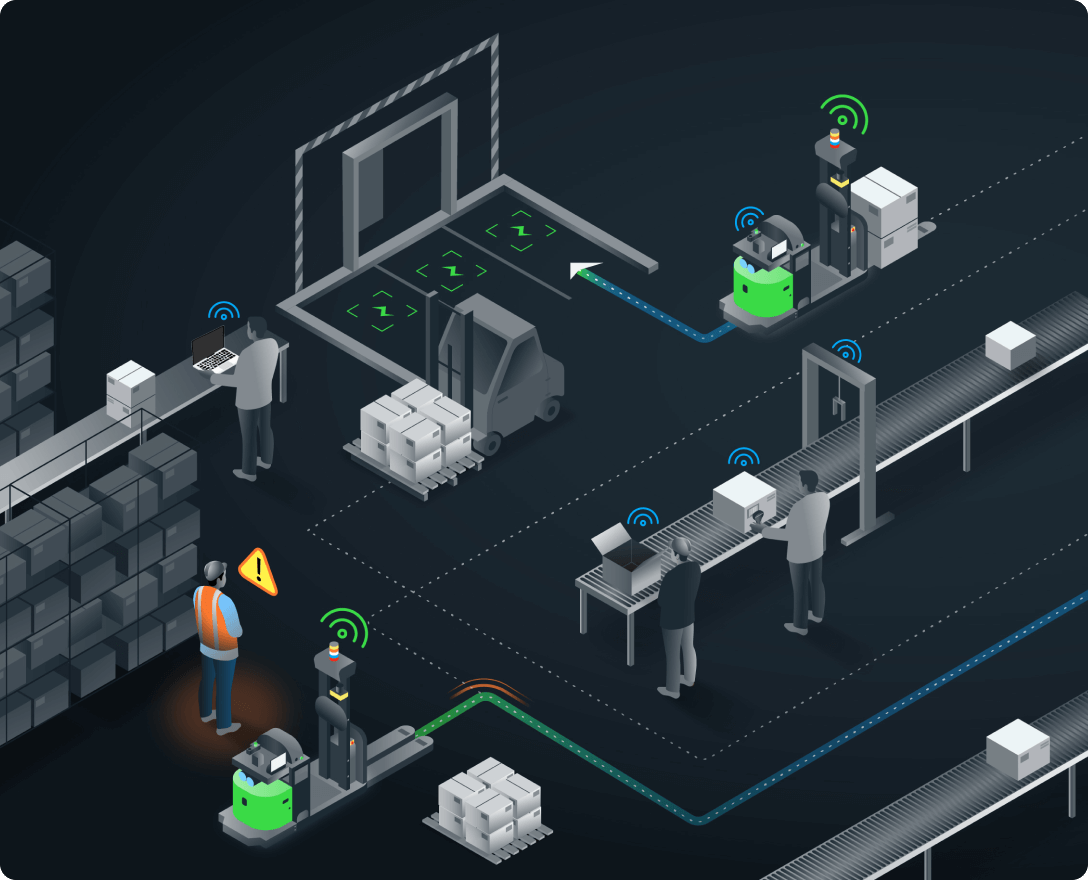

Gone are the days of unconnected, “dumb” equipment. Today, small and large devices situated at the “edge” need constant connectivity. It’s essential for basic functions, communication between devices and your team, monitoring and updates, and fully harnessing analytics’ power to amplify your operations.

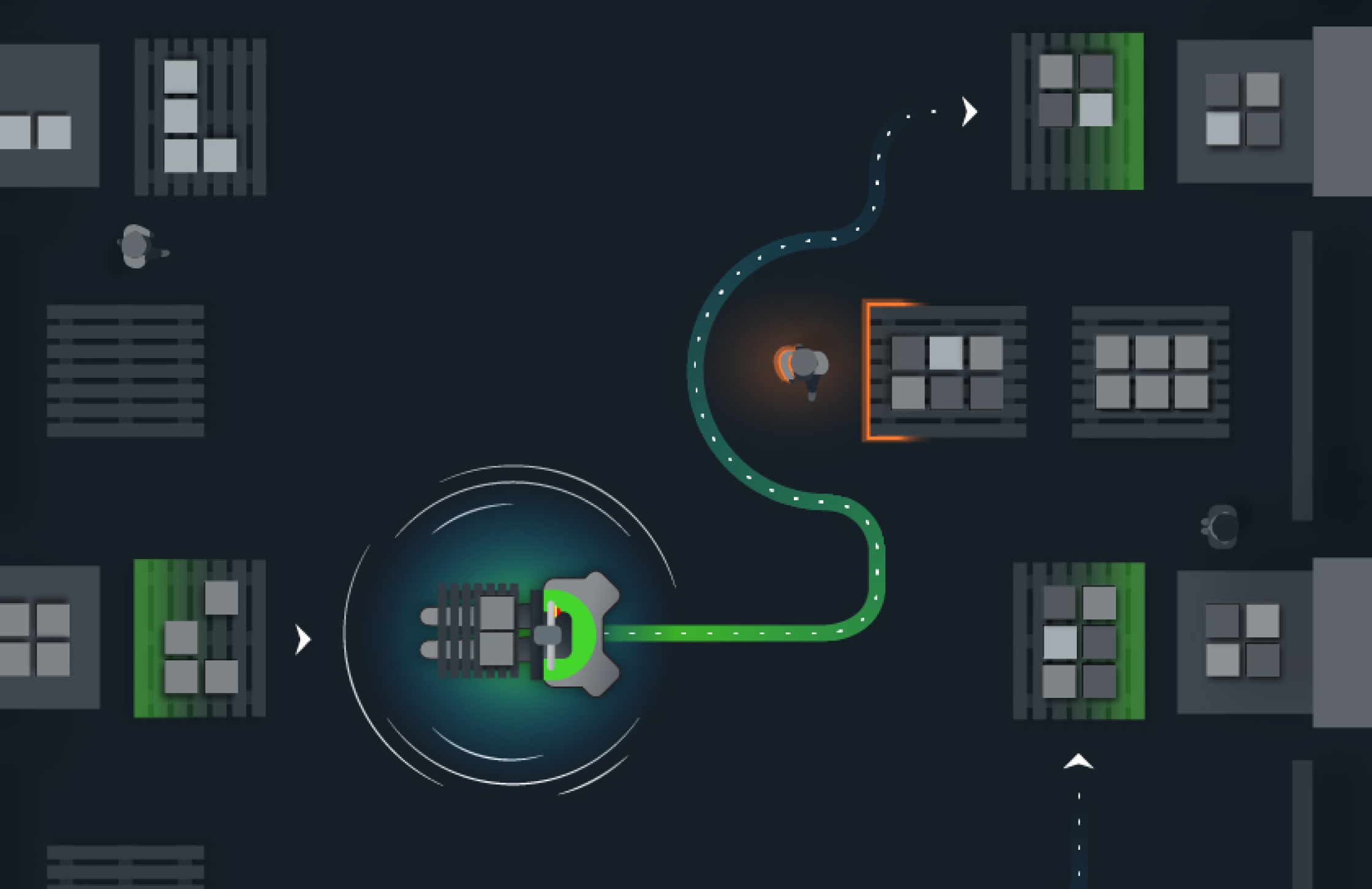

But none of this is possible without equipping your facility with the right high-speed wireless. And for those eyeing autonomous mobile robots? The stakes are even higher.

Prioritizing connectivity is essential in order to:

- Speed up automation deployment

- Provide upgraded cyber-protection

- Scale with the growth of your operation

- Improve overall automation performance

- Allow for cutting-edge software updates and remote services like monitoring

- Add new connected devices in your facility

Industrial environments demand more

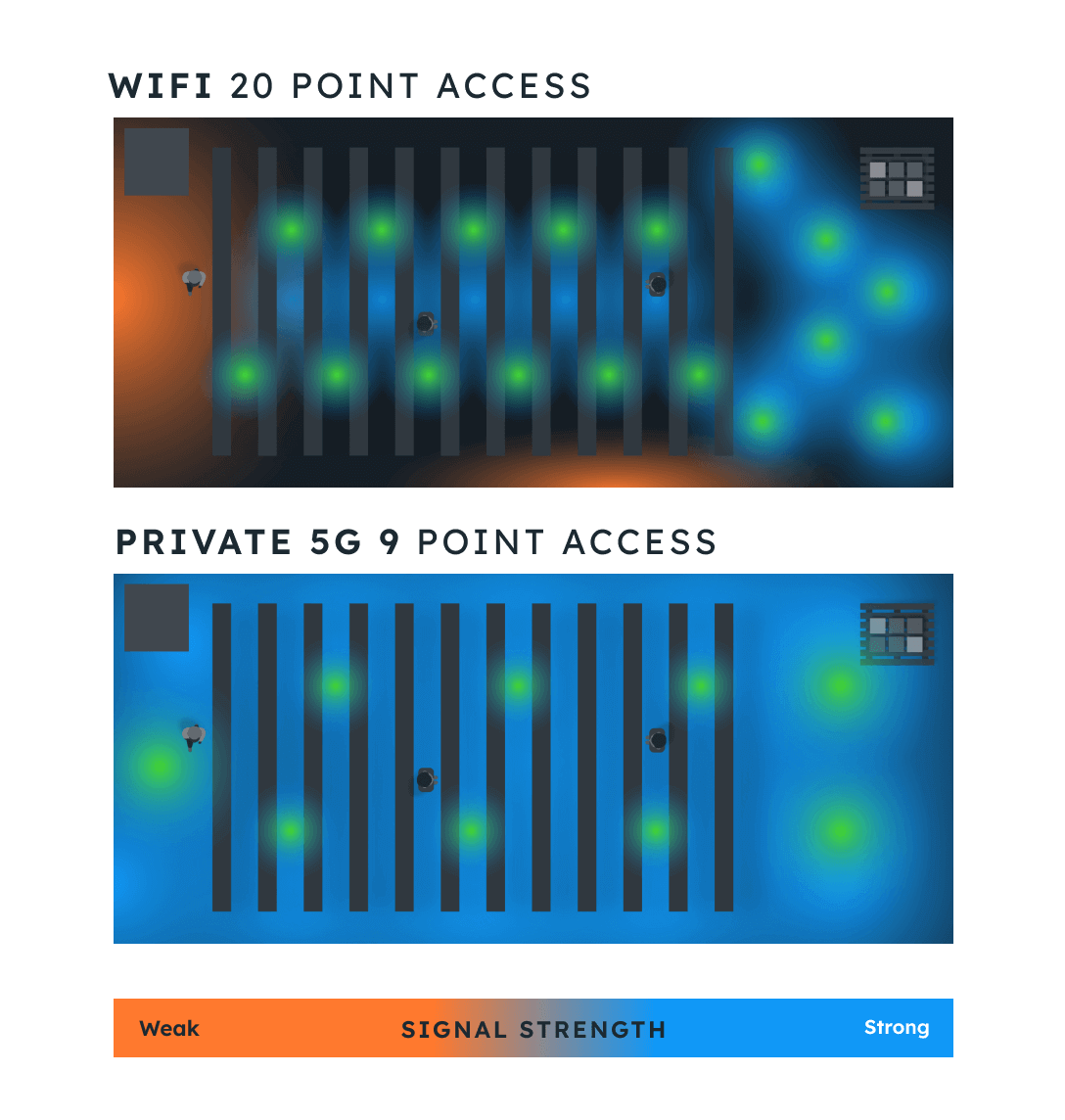

Just as not all cars are crafted for off-roading or extreme weather, Wi-Fi isn’t tailored to withstand the challenges of industrial settings. Warehouses teem with materials like steel and concrete that induce connectivity dead zones.

Add to that the constant movement of machinery and personnel, and you get an unpredictable landscape. These elements combine to make maintaining robust Wi-Fi connectivity exceptionally challenging.

Connectivity issues come with costs

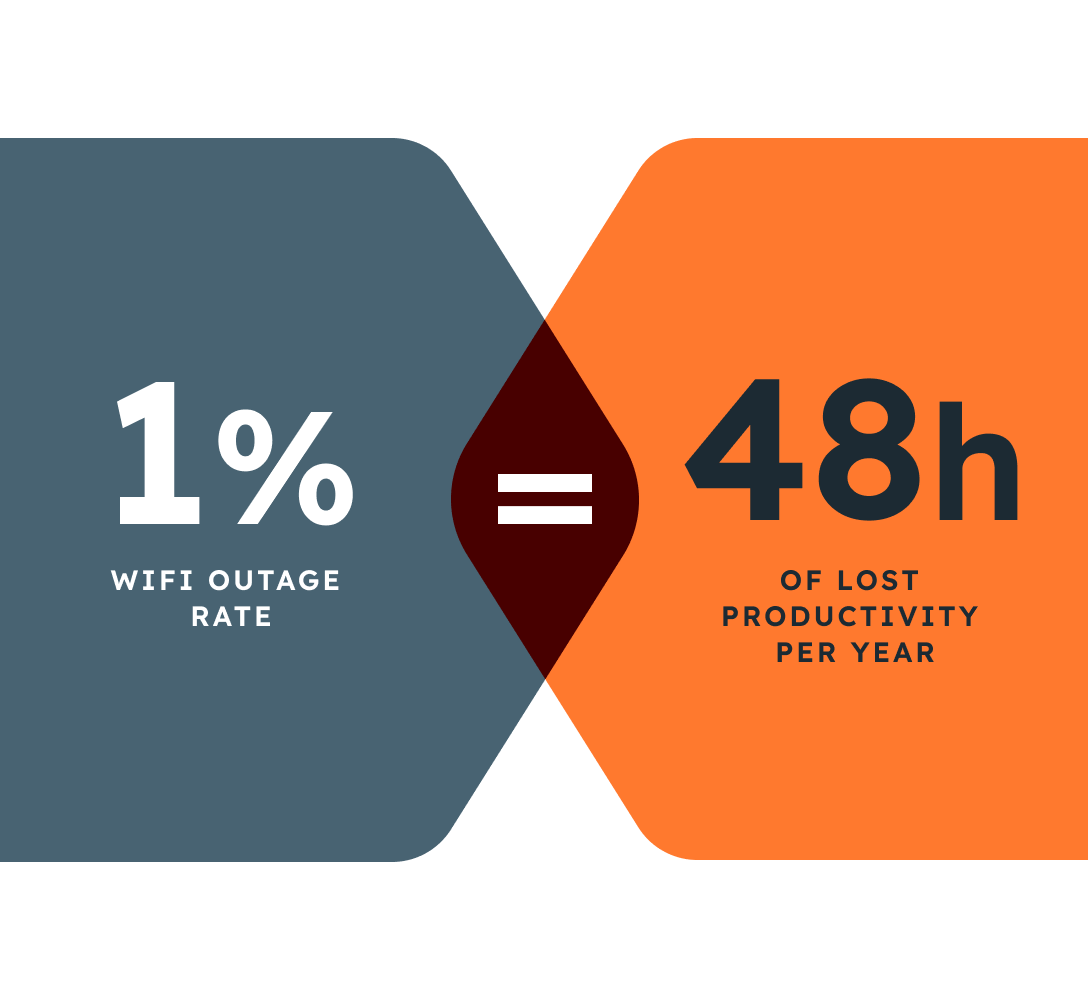

While many view connectivity disruptions as a minor business expense, their implications are far-reaching — beyond just interrupting a Netflix session.

Spotty or slow Wi-Fi in a facility can lead to schedule upheavals, service lags, safety hazards, and significant productivity losses that can accumulate quickly.

You have options

Explore the pros and cons of each wireless option to determine the best fit for your operations, keeping in mind efficiency, security, and scalability.

Good ol’ Wi-Fi

Private cellular from carriers

Managed 5G as a service

Private 5G is the network that delivers clear benefits:

Private cellular is still ideal for logistics operations:

Still underestimating connectivity?

Think you don’t need to worry about connectivity for automation solutions? That myth is busted. Along with special guest, Brian Watkins, EVP of Betacom, our team dives into 5G as a Service (5GaaS) and why connectivity is a critical component of material handling automation success.

reduce your risk

Focused on security

Wi-Fi’s unmanaged and unlicensed structure can introduce security vulnerabilities. In contrast, managed 5G is fortified with built-in security protocols. These protocols regulate device access, safeguard your data, and ensure its encryption. Thus, even if your Wi-Fi faces a breach, your warehouse IoT and automation tools on private 5G remain unaffected, ensuring uninterrupted operations.

83%

Companies with more than one data breach

$9.44

Million is the average cost of a data breach in the US

277

Days is the average time to detect and contain a data breach

Go with a leader

Vecna Robotics is proud to partner with Betacom, a leader and innovator in the 5GaaS space